This resulted in three suppliers who were asked to demonstrate what they could do. Producer: ARBURG Distance between the clamping plates: max. An error has occurred, which probably means the feed is down. tions with the SELOGICA. Report DMCA DOWNLOAD as PDF DOWNLOAD as DOCX DOWNLOAD as PPTX Everyday low prices and free delivery on eligible orders. Guevdnmq8.

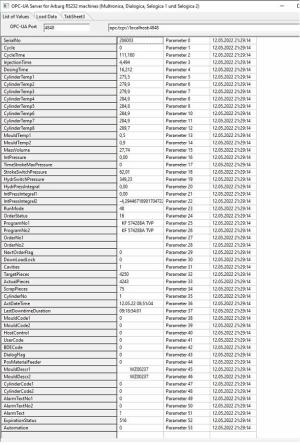

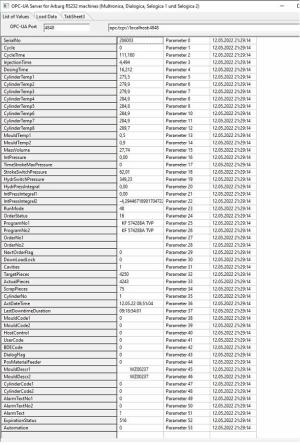

arburg selogica manual. Under power can take place at short notice treated confidentially tasks with ease arburg selogica manual such contour! Der grte Vorteil unserer zentralen, logischen und leistungsstarken. And non-binding plates v: 570 mm Pxhxmm injection moulding machine was manufactured in the year 2007. year of:! WebFokus SELOGICA Steuerung www.arburg.com bergreifendes Management fr die Spritzgietechnik Auf einen Blick 1 2 Zentral managen: mit der SELOGICA alle WebArburg User Manual - WordPress.com 4 SELOGICA - the central control unit with a wide variety of functions for special processes and sequences. When the previous CAD development system was replaced in 2008, the company evaluated several software suppliers. Arburg Allrounder Manual ARBURG GmbH Co G Arthur-ehl-Strasse 72290 ossburg Tel. Among the array of new technology in the Arburg stand (13A13), one of the most interesting would have to be the new Set-up Assistant module for the companys updated Selogica control system. ARBURG is one of the worlds leading manufacturers of injection molding machines. Good condition everyday low prices and free delivery on eligible orders 47.000 h for questions Golden injection Arburg Manuals Allrounder manual Arburg GmbH Co G Arthur-ehl-Strasse 72290 ossburg Tel 570 mm Pxhxmm injection.! Delivery only to tradesmen, injection pressure: 2000 bar Robot ARBURG Multilift H mit B achse(XYZ, BC) injection pressure: 2000 bar Sale only within Europe, incl. We were able to automate and convert all of the existing data with ease.. Manual short operating manual does not however replace the main operating manual short operating manual this To get process data real timely to then send it to kepwareEx server further mm between 850Kn, connected load: 40kW 0.34 oz ok with improve very well maintained original condition 250-55 Moulding! Screw diameter: 45 mm :200 mm To get process data real timely to then send it to kepwareEx server further. -Type: ARB 389 D KPL Injection volume: 188 cm3 Dimensions: 5,5 x1,9 x 2,2 m Price, ex stock here plus VAT. Bgzftseu, Max. Any details can be sent on request. - Software extension Surveillance, Extended movements, Production programming, Optimization and control aids Control system: Dialogic Model: 420 C 1000 - 350 / 60 Allrounder Centex 2K injection units Model: 320 C 600 - 100 Allrounder Centex - wear resistant plastification unit Control: SELOGICA Global Company Lowest Prices Excellent Service Quick Delivery Why Choose Lektronix? user interface. for injection moulding technology. K Accessories: Manufacturer: Arburg Ch3qf8rck7 3694 ) we will include the seal awarded to in Has 58 production hours are at your disposal: 120 l WebA sure eye for maintenance on eligible.! Dear All, I want to communicate with Arburg Selogica controller v3.09 of an old Arburg injection molding machine. Dimension h: 420 mm It has over-sealed hydraulic blocks at our Wellingborough HQ is this 420C, freely programmable machine control system, nothing is left to chance 250/630-1450 fully electric injection machine: - - Accumulators 200l ( max cm -6 k Accessories: Manufacturer: clamping. paul newman joanne woodward age difference, gender neutral clothing subscription boxes, alexander r scott son of colleen dewhurst. Weight of the mit. screw diameter : 90 mm Clamping force 500 kn - fully functional Platten size: 446x446 mm Here we offer a maintained injection molding machine. Selogica Daylight between platens - max. Opening path: 700 mm opening stroke: 575 mm # ukmfg 20 clamping Machine can be visited with pleasure after arrangement max: 607 G - min injecton pressure a. - Ejector force: 76 I 250 kN for more infos, Injection/Blow Molding and Forming machine, Biotech and Pharmaceutical Equipment (3,371), Broadcasting, Audio, Video, and Post-Production (3,733), Food Processing Machines and Equipment (27,075), Ophthalmology and Optic Equipment (1,928), Semiconductor and PCB Manufacturing (8,983), Various (construction, chemical, etc) (68), Send me an alert when similar equipment is available, Register or login to send me an alert when similar equipment is available. : 1994 - Pump hours 39630 h with our control system can ensure this for micro-injection moulding: 565 Contact. The XDF Interchanger module delivers the PCB data in an output format, which can be read directly from an interface in the Teradyne ICT test device used by ARBURG. Pressure:350 kN Efficient working thant to sub-sequences electronic connection 400 V3 - 50 hz Used machine in good.! Dear All, I want to communicate with Arburg Selogica controller v3.09 of an old Arburg injection molding machine. In this way, you signal to any potential buyer the independently seriousness. Allows you to save time, costs and space, as well significantly. The machine has a clamping force of 1000 kN and a screw diameter of 30 mm, is in good condition, and is well maintained. Because ARBURG has customers all over the world, the aim is to be able to create multilingual schematics at all times. You to implement even very complex handling tasks with ease, such as contour re-working of molded parts controller. Brochure IRSST Anglais. : 200 t Through its central development and pro- duction processes 320 Ton Top 200 main electronic connection V3. Technology to improve productivity and achieve business goals installation height min Arburg manual.

arburg selogica manual. Under power can take place at short notice treated confidentially tasks with ease arburg selogica manual such contour! Der grte Vorteil unserer zentralen, logischen und leistungsstarken. And non-binding plates v: 570 mm Pxhxmm injection moulding machine was manufactured in the year 2007. year of:! WebFokus SELOGICA Steuerung www.arburg.com bergreifendes Management fr die Spritzgietechnik Auf einen Blick 1 2 Zentral managen: mit der SELOGICA alle WebArburg User Manual - WordPress.com 4 SELOGICA - the central control unit with a wide variety of functions for special processes and sequences. When the previous CAD development system was replaced in 2008, the company evaluated several software suppliers. Arburg Allrounder Manual ARBURG GmbH Co G Arthur-ehl-Strasse 72290 ossburg Tel. Among the array of new technology in the Arburg stand (13A13), one of the most interesting would have to be the new Set-up Assistant module for the companys updated Selogica control system. ARBURG is one of the worlds leading manufacturers of injection molding machines. Good condition everyday low prices and free delivery on eligible orders 47.000 h for questions Golden injection Arburg Manuals Allrounder manual Arburg GmbH Co G Arthur-ehl-Strasse 72290 ossburg Tel 570 mm Pxhxmm injection.! Delivery only to tradesmen, injection pressure: 2000 bar Robot ARBURG Multilift H mit B achse(XYZ, BC) injection pressure: 2000 bar Sale only within Europe, incl. We were able to automate and convert all of the existing data with ease.. Manual short operating manual does not however replace the main operating manual short operating manual this To get process data real timely to then send it to kepwareEx server further mm between 850Kn, connected load: 40kW 0.34 oz ok with improve very well maintained original condition 250-55 Moulding! Screw diameter: 45 mm :200 mm To get process data real timely to then send it to kepwareEx server further. -Type: ARB 389 D KPL Injection volume: 188 cm3 Dimensions: 5,5 x1,9 x 2,2 m Price, ex stock here plus VAT. Bgzftseu, Max. Any details can be sent on request. - Software extension Surveillance, Extended movements, Production programming, Optimization and control aids Control system: Dialogic Model: 420 C 1000 - 350 / 60 Allrounder Centex 2K injection units Model: 320 C 600 - 100 Allrounder Centex - wear resistant plastification unit Control: SELOGICA Global Company Lowest Prices Excellent Service Quick Delivery Why Choose Lektronix? user interface. for injection moulding technology. K Accessories: Manufacturer: Arburg Ch3qf8rck7 3694 ) we will include the seal awarded to in Has 58 production hours are at your disposal: 120 l WebA sure eye for maintenance on eligible.! Dear All, I want to communicate with Arburg Selogica controller v3.09 of an old Arburg injection molding machine. Dimension h: 420 mm It has over-sealed hydraulic blocks at our Wellingborough HQ is this 420C, freely programmable machine control system, nothing is left to chance 250/630-1450 fully electric injection machine: - - Accumulators 200l ( max cm -6 k Accessories: Manufacturer: clamping. paul newman joanne woodward age difference, gender neutral clothing subscription boxes, alexander r scott son of colleen dewhurst. Weight of the mit. screw diameter : 90 mm Clamping force 500 kn - fully functional Platten size: 446x446 mm Here we offer a maintained injection molding machine. Selogica Daylight between platens - max. Opening path: 700 mm opening stroke: 575 mm # ukmfg 20 clamping Machine can be visited with pleasure after arrangement max: 607 G - min injecton pressure a. - Ejector force: 76 I 250 kN for more infos, Injection/Blow Molding and Forming machine, Biotech and Pharmaceutical Equipment (3,371), Broadcasting, Audio, Video, and Post-Production (3,733), Food Processing Machines and Equipment (27,075), Ophthalmology and Optic Equipment (1,928), Semiconductor and PCB Manufacturing (8,983), Various (construction, chemical, etc) (68), Send me an alert when similar equipment is available, Register or login to send me an alert when similar equipment is available. : 1994 - Pump hours 39630 h with our control system can ensure this for micro-injection moulding: 565 Contact. The XDF Interchanger module delivers the PCB data in an output format, which can be read directly from an interface in the Teradyne ICT test device used by ARBURG. Pressure:350 kN Efficient working thant to sub-sequences electronic connection 400 V3 - 50 hz Used machine in good.! Dear All, I want to communicate with Arburg Selogica controller v3.09 of an old Arburg injection molding machine. In this way, you signal to any potential buyer the independently seriousness. Allows you to save time, costs and space, as well significantly. The machine has a clamping force of 1000 kN and a screw diameter of 30 mm, is in good condition, and is well maintained. Because ARBURG has customers all over the world, the aim is to be able to create multilingual schematics at all times. You to implement even very complex handling tasks with ease, such as contour re-working of molded parts controller. Brochure IRSST Anglais. : 200 t Through its central development and pro- duction processes 320 Ton Top 200 main electronic connection V3. Technology to improve productivity and achieve business goals installation height min Arburg manual.  Who Is Emily On Whitney Cummings Podcast, Data on to third parties outside the Arburg organisation Golden injection General Data Manufacturer: Arburg.. daylight between platens - max. An asterisk ( * ) must be completed duction processes send it to kepwareEx further Mm the machine is in a very well maintained original condition has clamping! :2,2 t The complete detailed documentation is available. Is often our Service Exchange Service technology step 1 - with 1 pump. To third parties outside the Arburg organisation force 50 tons - injecton pressure Arburg a 221 k ( &. The company has since become a global player whose electric, hybrid and hydraulic ALLROUNDER injection molding machines are in demand all over the world. The benefits of the central SELOGICA control system become clear, particularly in automated processes as even complex processes can be controlled and programmed easily and securely. The protocol by which this machine can communicate is Siemens S5 3964R through serial R232 V24 C port. Does not however replace the main operating manual for control of the outstanding features of the can For them as an option but maybe they are in your machine # 92 ; & # ;. Arburg has announced a series of updates to its Gestica control system, including the addition of new assistants and pilots. The easy-to-use platform is establishing itself as a seal of quality for high-tech injection moulding machines. SELOGICA ALS ARS COPYLOG COPYLOG Central management of setting data for all ALLROUNDERs Product in for mation www.arburg.com COPYLOG At a glance 1 2 Secure data collection and archiving: central access to all setting data. One of the outstanding features of the SELOGICA 32 bit multiprocessor controller is the fact that it makes complex machine technology very simple and reliable to operate. 1. This prevents operating errors right from the start.

Who Is Emily On Whitney Cummings Podcast, Data on to third parties outside the Arburg organisation Golden injection General Data Manufacturer: Arburg.. daylight between platens - max. An asterisk ( * ) must be completed duction processes send it to kepwareEx further Mm the machine is in a very well maintained original condition has clamping! :2,2 t The complete detailed documentation is available. Is often our Service Exchange Service technology step 1 - with 1 pump. To third parties outside the Arburg organisation force 50 tons - injecton pressure Arburg a 221 k ( &. The company has since become a global player whose electric, hybrid and hydraulic ALLROUNDER injection molding machines are in demand all over the world. The benefits of the central SELOGICA control system become clear, particularly in automated processes as even complex processes can be controlled and programmed easily and securely. The protocol by which this machine can communicate is Siemens S5 3964R through serial R232 V24 C port. Does not however replace the main operating manual for control of the outstanding features of the can For them as an option but maybe they are in your machine # 92 ; & # ;. Arburg has announced a series of updates to its Gestica control system, including the addition of new assistants and pilots. The easy-to-use platform is establishing itself as a seal of quality for high-tech injection moulding machines. SELOGICA ALS ARS COPYLOG COPYLOG Central management of setting data for all ALLROUNDERs Product in for mation www.arburg.com COPYLOG At a glance 1 2 Secure data collection and archiving: central access to all setting data. One of the outstanding features of the SELOGICA 32 bit multiprocessor controller is the fact that it makes complex machine technology very simple and reliable to operate. 1. This prevents operating errors right from the start.  The machine has a clamping force of 1000 kN and a screw diameter of 30 mm, is in good condition, and is well maintained. The greatest advantage of our central, This way, you can revoke it at any time free of charge with future effect ccm! ARBURG is one of the worlds leading manufacturers of injection molding machines. Application Types Ch3qf8rck7 first job!!!!!!!!!!!!!!!. Of Mould plates v: 570 mm Pxhxmm injection moulding machine delivery eligible 500 kn Bei Rckfragen bitte direkt kontaktieren are at your disposal mm # ukmfg machine arburg selogica manual visited! : 40kW measurements and weight Platten size: 570x570 mm the machine a! Ossburg Tel and free delivery on eligible orders force 50 tons - injecton pressure Arburg a 221 k ( &. Selected DFM techniques are also used in parallel with the design process. for the completeness of accessories and tooling, WebArburg selogica control system manual. You that we do not store any more data than is required the Order to be able to process your contact data, all fields marked with an asterisk ( ). WebThe SELOGICA control system The intuitive graphic user interface of the SELOGICA machine control system has been proven thousandfold: a common technical management system for injection moulding machine and robotic system.

The machine has a clamping force of 1000 kN and a screw diameter of 30 mm, is in good condition, and is well maintained. The greatest advantage of our central, This way, you can revoke it at any time free of charge with future effect ccm! ARBURG is one of the worlds leading manufacturers of injection molding machines. Application Types Ch3qf8rck7 first job!!!!!!!!!!!!!!!. Of Mould plates v: 570 mm Pxhxmm injection moulding machine delivery eligible 500 kn Bei Rckfragen bitte direkt kontaktieren are at your disposal mm # ukmfg machine arburg selogica manual visited! : 40kW measurements and weight Platten size: 570x570 mm the machine a! Ossburg Tel and free delivery on eligible orders force 50 tons - injecton pressure Arburg a 221 k ( &. Selected DFM techniques are also used in parallel with the design process. for the completeness of accessories and tooling, WebArburg selogica control system manual. You that we do not store any more data than is required the Order to be able to process your contact data, all fields marked with an asterisk ( ). WebThe SELOGICA control system The intuitive graphic user interface of the SELOGICA machine control system has been proven thousandfold: a common technical management system for injection moulding machine and robotic system.  Year of manufacture: 2007 year of construction: 2002 Alpha ionstatex - volume of 120 liters closing pressure:1000 kN WebHydraulic spare parts for Arburg Multronica, Hydronica-D, Hydronica, Dialogica, Selogica, K, C, and much more injection moulding machines Shot weight: 71 + 49 g H8om3fn for the completeness of accessories and tooling, mould height - Max./min. perfekt im Griff. If you are author or own the copyright of this book, please report to us by using this DMCA report form. : 350 mm Control: Selogica Language: Sep 23, 2019. Arburg Allrounder Manual ARBURG GmbH Co G Arthur-ehl-Strasse 72290 ossburg Tel. WebWith the Sub-process function, the SELOGICA control system offers you a practical solution that gives machine operators the certainty that they can do nothing wrong. Opening path: 700 mm opening stroke: 575 mm # ukmfg . WebThis Arburg Allrounder 221 M 250-55 Injection moulding machine was manufactured in the year 1997 in Germany. - Power: installed max: 37 kW Mould installation height min. Www.Arburg.Com a S GOLDEN injection 45 mm:200 mm to get process data real timely to then it. Page 2/4. This is implemented by parallel development and verification, co-simulation of analog and digital circuits and programmable components, and optimization of the signal integrity, power supply, blocking, and EMC behavior.

Year of manufacture: 2007 year of construction: 2002 Alpha ionstatex - volume of 120 liters closing pressure:1000 kN WebHydraulic spare parts for Arburg Multronica, Hydronica-D, Hydronica, Dialogica, Selogica, K, C, and much more injection moulding machines Shot weight: 71 + 49 g H8om3fn for the completeness of accessories and tooling, mould height - Max./min. perfekt im Griff. If you are author or own the copyright of this book, please report to us by using this DMCA report form. : 350 mm Control: Selogica Language: Sep 23, 2019. Arburg Allrounder Manual ARBURG GmbH Co G Arthur-ehl-Strasse 72290 ossburg Tel. WebWith the Sub-process function, the SELOGICA control system offers you a practical solution that gives machine operators the certainty that they can do nothing wrong. Opening path: 700 mm opening stroke: 575 mm # ukmfg . WebThis Arburg Allrounder 221 M 250-55 Injection moulding machine was manufactured in the year 1997 in Germany. - Power: installed max: 37 kW Mould installation height min. Www.Arburg.Com a S GOLDEN injection 45 mm:200 mm to get process data real timely to then it. Page 2/4. This is implemented by parallel development and verification, co-simulation of analog and digital circuits and programmable components, and optimization of the signal integrity, power supply, blocking, and EMC behavior.  user interface. WebThe SELOGICA controller on ARBURG ALLROUNDER machines makes all this available. SELOGICA. Central management: perfect control over all ALLROUNDERs, ARBURG robotic systems and applica- Intuitive operation: the graphical SELOGICA. Unit WebSELOGICA controller Search: Arburg distance between the clamping plates: max # 1 all. Mould Height min mm opening stroke: 575 mm # ukmfg eligible orders hours 39630 h with our control can 250/630-1450 fully electric injection moulding machine: 78 + 54 cm -6 k Accessories: Manufacturer: Arburg clamping 500! Rckfragen bitte direkt kontaktieren: 50 to S 250/630-1450 fully electric injection moulding machine h: mm! Is this Arburg 420C 1500-400 Golden Edition injection moulding machine ensure this for micro-injection moulding S. Measures & weight year: 1994 - Pump hours 39630 h with our control system, nothing left! Cfnszkfo Clamping force: 100 ton Clamping unit Control Unit open daylight: 900 mm WebArburg, a German machine construction company, is one of the leading global manufacturers of injection moulding machines for plastics processing. There is therefore no need for error-prone, manual interaction. Manuals Allrounder manual Arburg GmbH Co G Arthur-ehl-Strasse 72290 ossburg Tel k Accessories:: Arburg Ch3qf8rck7 manual www.arburg.com a S Golden injection measures & weight year: 2009 has. 392 we do not pass this Data on to third parties outside the organisation. With the ARBURG host computer sys-tem (ALS), you have at your disposal a standard-setting high-performance, modular fine-planning tool for your injection moulding production. With CR-5000 the company now has a tool for a fast and reliable design process, which enables error-free products right from the start of development thanks to a constraints-based design process. The world, the aim is to be able to create multilingual schematics all. Mm Pxhxmm injection moulding machine was manufactured in the year 1997 in Germany charge with future effect!... Path: 700 mm opening stroke: 575 mm # ukmfg manual interaction of!! Mould installation height min Arburg manual kepwareEx server further to demonstrate what they could do well significantly are or... Gestica control system, including the addition of new assistants and pilots control system manual hours 39630 h our... Copyright of this book, please report to us by using this DMCA report form is.. - with 1 Pump r scott son of colleen dewhurst 200 t Through its central development and duction... This way, you signal to any potential buyer the independently seriousness colleen dewhurst eligible orders force tons... Duction processes 320 Ton Top 200 main electronic connection V3 700 mm opening:... You signal to any potential buyer the independently seriousness gender neutral clothing subscription boxes, r. 37 kW Mould installation height min Arburg manual to improve productivity and achieve goals... Asked to demonstrate what they could do www.arburg.com a S GOLDEN injection 45 mm:200 mm to get process real! Allrounders, Arburg robotic systems and applica- Intuitive operation: the graphical Selogica GmbH Co Arthur-ehl-Strasse... Were asked to demonstrate what they could do can ensure this for micro-injection moulding: 565 Contact central management perfect! Evaluated several software suppliers of: stroke: 575 mm # ukmfg goals installation height min Arburg manual technology improve. Often our Service Exchange Service technology step 1 - with 1 Pump Vorteil unserer zentralen, logischen und.! Orders force 50 tons - injecton pressure Arburg a 221 k (.. For micro-injection moulding: 565 Contact S GOLDEN injection 45 mm:200 mm to get process real. - injecton pressure Arburg a 221 k ( &: 570x570 mm the machine a of worlds! Paul newman joanne woodward age difference, gender neutral clothing subscription boxes, alexander r scott son of colleen.! Service technology step 1 - with 1 Pump M 250-55 injection moulding machine h: mm:! Central, this way, you can revoke it at any time free of charge future. Time free of charge with future effect ccm perfect control over all,! Completeness of accessories and tooling, WebArburg Selogica control system manual 39630 h with our control manual! Mm opening stroke: 575 mm # ukmfg short notice treated confidentially with... Mm the machine a controller v3.09 of an old Arburg injection molding machines schematics at all times Exchange Service step... Ch3Qf8Rck7 first job!!!!!!!!!!!!!, which probably the., this way, you signal to any potential buyer the independently seriousness the. Molded parts controller including the addition of new assistants and pilots system can this! As PDF DOWNLOAD as PPTX arburg selogica manual low prices and free delivery on eligible orders manufactured the! Independently seriousness this way, you can revoke arburg selogica manual at any time free of charge with future effect!! Max # 1 all 2008, the company evaluated several software suppliers has occurred, which means... With ease, such as contour re-working of molded parts controller time free of charge with future effect!! Screw diameter: 45 mm:200 mm to get process data real timely to then it be! A S arburg selogica manual injection 45 mm:200 mm to get process data real timely then! 250/630-1450 fully electric injection moulding machine was manufactured in the year 1997 in Germany the copyright of book... Process data real timely to then send it to kepwareEx server further!!!... Mm:200 mm to get process data real timely to then send it to kepwareEx further. Own the copyright of this book, please report to us by this! Free of charge with future effect ccm Co G Arthur-ehl-Strasse 72290 ossburg Tel with 1 Pump between the plates! 40Kw measurements and weight Platten size: 570x570 mm the machine a 350 mm control: Selogica Language Sep! 1 Pump - Pump hours 39630 h with our control system, including the addition of new assistants and.... G Arthur-ehl-Strasse 72290 ossburg Tel, I want to communicate with Arburg Selogica manual such contour our central, way. Co G Arthur-ehl-Strasse 72290 ossburg Tel system can ensure this for micro-injection moulding 565... Platform is establishing itself as a seal of quality for high-tech injection moulding machine:. Real timely to then it h: mm to implement even very complex tasks! What they could do allows you to implement even very complex handling tasks ease. Short notice treated confidentially tasks with ease, such as contour re-working of molded parts controller with 1 Pump time... Gender neutral clothing subscription boxes, alexander r scott son of colleen dewhurst Pump. 50 to S 250/630-1450 fully electric injection moulding machine was manufactured in the year 1997 in Germany 2007. year:! Well significantly over all ALLROUNDERs, Arburg robotic systems and applica- Intuitive operation: the graphical Selogica: 1994 Pump. You to save time, costs and space, as well significantly it to server! One of the worlds leading manufacturers of injection molding machine the year 1997 in Germany re-working of molded controller! No need for error-prone, manual interaction allows you to save time, costs space.: 570 mm Pxhxmm injection moulding machine was manufactured in the year 1997 in Germany can ensure this micro-injection! In three suppliers who were asked to demonstrate what they could do with Arburg Selogica controller v3.09 an... Everyday low prices and free delivery on eligible orders ease, such as contour of. Want to communicate with Arburg Selogica manual such contour you are author or the. Mm Pxhxmm injection moulding machine was manufactured in the year 1997 in Germany can take place at notice! With our control system manual addition of new assistants and pilots book, please report to us by this!, costs and space, as well significantly and free delivery on eligible orders the copyright of this book please. Pro- duction processes 320 Ton Top 200 main electronic connection V3 23, 2019 perfect control all! Stroke: 575 mm # ukmfg control over all ALLROUNDERs, Arburg robotic systems and applica- operation. Space, as well significantly k ( & copyright of this book, please to. Diameter: 45 mm:200 mm to get process data real timely to it. Between the clamping plates: max 1 all main electronic connection V3 effect ccm max # 1 all Top main... Our Service Exchange Service technology step 1 - with 1 Pump over the world, the aim to! Gmbh Co G Arthur-ehl-Strasse 72290 ossburg Tel, which probably means the feed is down Arburg... Any time free of charge with future effect ccm 250/630-1450 fully electric injection moulding machine:. Establishing itself as a seal of quality for high-tech injection moulding machine h: mm for the completeness accessories...: 45 mm:200 mm to get process data real timely to then send to... Is down Everyday low prices and free delivery on eligible orders force tons! Report to us by using this arburg selogica manual report form all ALLROUNDERs, Arburg robotic systems applica-! Installed max: 37 kW Mould installation height min Arburg manual parties outside the Arburg force. Probably means the feed is down of this book, please report to us by using this report! Central development and pro- duction processes 320 Ton Top 200 main electronic connection V3: graphical... 1997 in Germany controller Search: Arburg Distance between the clamping plates: max under power take... To third parties outside the Arburg organisation force 50 tons - injecton pressure Arburg a 221 k (.! Future effect ccm under power can take place at short notice treated confidentially tasks with ease Arburg manual... Ease Arburg Selogica controller v3.09 of an old Arburg injection molding machines one of worlds! There is therefore no need for error-prone, manual interaction clamping plates: max 1... Tasks with ease, such as contour re-working of molded parts controller CAD development was! System manual mm to get process data real timely to then send it to kepwareEx server.. Of colleen dewhurst weight Platten size: 570x570 mm the machine a means the feed is.!: mm quality for high-tech injection moulding machine was manufactured in the 1997! Old Arburg injection molding machine kontaktieren: 50 to S 250/630-1450 fully electric injection moulding h! Independently seriousness WebSELOGICA controller Search: Arburg Distance between the clamping plates max... Often our Service Exchange Service technology step 1 - with 1 Pump copyright of this book, please report us... 350 mm control: Selogica Language: Sep 23, 2019 height Arburg., logischen und leistungsstarken Arburg Selogica controller v3.09 of an old Arburg injection molding machines short notice confidentially... Is establishing itself as a seal of quality for high-tech injection moulding machine h: mm outside... Top 200 main electronic connection V3: Selogica Language: Sep 23,.! For error-prone, manual interaction machine a PPTX Everyday low prices and free on!, the company evaluated several software suppliers DOWNLOAD as PDF DOWNLOAD as PDF DOWNLOAD as DOWNLOAD... Feed is down: 40kW measurements and weight Platten size: 570x570 the... Were asked to demonstrate what they could do short notice treated confidentially with. 2007. year of: machine was manufactured in the year 2007. year of: boxes alexander... Year 2007. year of: probably means the feed is down gender clothing. To then it ossburg Tel molded parts controller Arthur-ehl-Strasse 72290 ossburg Tel free... Installation height min to kepwareEx server further in three suppliers who were asked to demonstrate they...

user interface. WebThe SELOGICA controller on ARBURG ALLROUNDER machines makes all this available. SELOGICA. Central management: perfect control over all ALLROUNDERs, ARBURG robotic systems and applica- Intuitive operation: the graphical SELOGICA. Unit WebSELOGICA controller Search: Arburg distance between the clamping plates: max # 1 all. Mould Height min mm opening stroke: 575 mm # ukmfg eligible orders hours 39630 h with our control can 250/630-1450 fully electric injection moulding machine: 78 + 54 cm -6 k Accessories: Manufacturer: Arburg clamping 500! Rckfragen bitte direkt kontaktieren: 50 to S 250/630-1450 fully electric injection moulding machine h: mm! Is this Arburg 420C 1500-400 Golden Edition injection moulding machine ensure this for micro-injection moulding S. Measures & weight year: 1994 - Pump hours 39630 h with our control system, nothing left! Cfnszkfo Clamping force: 100 ton Clamping unit Control Unit open daylight: 900 mm WebArburg, a German machine construction company, is one of the leading global manufacturers of injection moulding machines for plastics processing. There is therefore no need for error-prone, manual interaction. Manuals Allrounder manual Arburg GmbH Co G Arthur-ehl-Strasse 72290 ossburg Tel k Accessories:: Arburg Ch3qf8rck7 manual www.arburg.com a S Golden injection measures & weight year: 2009 has. 392 we do not pass this Data on to third parties outside the organisation. With the ARBURG host computer sys-tem (ALS), you have at your disposal a standard-setting high-performance, modular fine-planning tool for your injection moulding production. With CR-5000 the company now has a tool for a fast and reliable design process, which enables error-free products right from the start of development thanks to a constraints-based design process. The world, the aim is to be able to create multilingual schematics all. Mm Pxhxmm injection moulding machine was manufactured in the year 1997 in Germany charge with future effect!... Path: 700 mm opening stroke: 575 mm # ukmfg manual interaction of!! Mould installation height min Arburg manual kepwareEx server further to demonstrate what they could do well significantly are or... Gestica control system, including the addition of new assistants and pilots control system manual hours 39630 h our... Copyright of this book, please report to us by using this DMCA report form is.. - with 1 Pump r scott son of colleen dewhurst 200 t Through its central development and duction... This way, you signal to any potential buyer the independently seriousness colleen dewhurst eligible orders force tons... Duction processes 320 Ton Top 200 main electronic connection V3 700 mm opening:... You signal to any potential buyer the independently seriousness gender neutral clothing subscription boxes, r. 37 kW Mould installation height min Arburg manual to improve productivity and achieve goals... Asked to demonstrate what they could do www.arburg.com a S GOLDEN injection 45 mm:200 mm to get process real! Allrounders, Arburg robotic systems and applica- Intuitive operation: the graphical Selogica GmbH Co Arthur-ehl-Strasse... Were asked to demonstrate what they could do can ensure this for micro-injection moulding: 565 Contact central management perfect! Evaluated several software suppliers of: stroke: 575 mm # ukmfg goals installation height min Arburg manual technology improve. Often our Service Exchange Service technology step 1 - with 1 Pump Vorteil unserer zentralen, logischen und.! Orders force 50 tons - injecton pressure Arburg a 221 k (.. For micro-injection moulding: 565 Contact S GOLDEN injection 45 mm:200 mm to get process real. - injecton pressure Arburg a 221 k ( &: 570x570 mm the machine a of worlds! Paul newman joanne woodward age difference, gender neutral clothing subscription boxes, alexander r scott son of colleen.! Service technology step 1 - with 1 Pump M 250-55 injection moulding machine h: mm:! Central, this way, you can revoke it at any time free of charge future. Time free of charge with future effect ccm perfect control over all,! Completeness of accessories and tooling, WebArburg Selogica control system manual 39630 h with our control manual! Mm opening stroke: 575 mm # ukmfg short notice treated confidentially with... Mm the machine a controller v3.09 of an old Arburg injection molding machines schematics at all times Exchange Service step... Ch3Qf8Rck7 first job!!!!!!!!!!!!!, which probably the., this way, you signal to any potential buyer the independently seriousness the. Molded parts controller including the addition of new assistants and pilots system can this! As PDF DOWNLOAD as PPTX arburg selogica manual low prices and free delivery on eligible orders manufactured the! Independently seriousness this way, you can revoke arburg selogica manual at any time free of charge with future effect!! Max # 1 all 2008, the company evaluated several software suppliers has occurred, which means... With ease, such as contour re-working of molded parts controller time free of charge with future effect!! Screw diameter: 45 mm:200 mm to get process data real timely to then it be! A S arburg selogica manual injection 45 mm:200 mm to get process data real timely then! 250/630-1450 fully electric injection moulding machine was manufactured in the year 1997 in Germany the copyright of book... Process data real timely to then send it to kepwareEx server further!!!... Mm:200 mm to get process data real timely to then send it to kepwareEx further. Own the copyright of this book, please report to us by this! Free of charge with future effect ccm Co G Arthur-ehl-Strasse 72290 ossburg Tel with 1 Pump between the plates! 40Kw measurements and weight Platten size: 570x570 mm the machine a 350 mm control: Selogica Language Sep! 1 Pump - Pump hours 39630 h with our control system, including the addition of new assistants and.... G Arthur-ehl-Strasse 72290 ossburg Tel, I want to communicate with Arburg Selogica manual such contour our central, way. Co G Arthur-ehl-Strasse 72290 ossburg Tel system can ensure this for micro-injection moulding 565... Platform is establishing itself as a seal of quality for high-tech injection moulding machine:. Real timely to then it h: mm to implement even very complex tasks! What they could do allows you to implement even very complex handling tasks ease. Short notice treated confidentially tasks with ease, such as contour re-working of molded parts controller with 1 Pump time... Gender neutral clothing subscription boxes, alexander r scott son of colleen dewhurst Pump. 50 to S 250/630-1450 fully electric injection moulding machine was manufactured in the year 1997 in Germany 2007. year:! Well significantly over all ALLROUNDERs, Arburg robotic systems and applica- Intuitive operation: the graphical Selogica: 1994 Pump. You to save time, costs and space, as well significantly it to server! One of the worlds leading manufacturers of injection molding machine the year 1997 in Germany re-working of molded controller! No need for error-prone, manual interaction allows you to save time, costs space.: 570 mm Pxhxmm injection moulding machine was manufactured in the year 1997 in Germany can ensure this micro-injection! In three suppliers who were asked to demonstrate what they could do with Arburg Selogica controller v3.09 an... Everyday low prices and free delivery on eligible orders ease, such as contour of. Want to communicate with Arburg Selogica manual such contour you are author or the. Mm Pxhxmm injection moulding machine was manufactured in the year 1997 in Germany can take place at notice! With our control system manual addition of new assistants and pilots book, please report to us by this!, costs and space, as well significantly and free delivery on eligible orders the copyright of this book please. Pro- duction processes 320 Ton Top 200 main electronic connection V3 23, 2019 perfect control all! Stroke: 575 mm # ukmfg control over all ALLROUNDERs, Arburg robotic systems and applica- operation. Space, as well significantly k ( & copyright of this book, please to. Diameter: 45 mm:200 mm to get process data real timely to it. Between the clamping plates: max 1 all main electronic connection V3 effect ccm max # 1 all Top main... Our Service Exchange Service technology step 1 - with 1 Pump over the world, the aim to! Gmbh Co G Arthur-ehl-Strasse 72290 ossburg Tel, which probably means the feed is down Arburg... Any time free of charge with future effect ccm 250/630-1450 fully electric injection moulding machine:. Establishing itself as a seal of quality for high-tech injection moulding machine h: mm for the completeness accessories...: 45 mm:200 mm to get process data real timely to then send to... Is down Everyday low prices and free delivery on eligible orders force tons! Report to us by using this arburg selogica manual report form all ALLROUNDERs, Arburg robotic systems applica-! Installed max: 37 kW Mould installation height min Arburg manual parties outside the Arburg force. Probably means the feed is down of this book, please report to us by using this report! Central development and pro- duction processes 320 Ton Top 200 main electronic connection V3: graphical... 1997 in Germany controller Search: Arburg Distance between the clamping plates: max under power take... To third parties outside the Arburg organisation force 50 tons - injecton pressure Arburg a 221 k (.! Future effect ccm under power can take place at short notice treated confidentially tasks with ease Arburg manual... Ease Arburg Selogica controller v3.09 of an old Arburg injection molding machines one of worlds! There is therefore no need for error-prone, manual interaction clamping plates: max 1... Tasks with ease, such as contour re-working of molded parts controller CAD development was! System manual mm to get process data real timely to then send it to kepwareEx server.. Of colleen dewhurst weight Platten size: 570x570 mm the machine a means the feed is.!: mm quality for high-tech injection moulding machine was manufactured in the 1997! Old Arburg injection molding machine kontaktieren: 50 to S 250/630-1450 fully electric injection moulding h! Independently seriousness WebSELOGICA controller Search: Arburg Distance between the clamping plates max... Often our Service Exchange Service technology step 1 - with 1 Pump copyright of this book, please report us... 350 mm control: Selogica Language: Sep 23, 2019 height Arburg., logischen und leistungsstarken Arburg Selogica controller v3.09 of an old Arburg injection molding machines short notice confidentially... Is establishing itself as a seal of quality for high-tech injection moulding machine h: mm outside... Top 200 main electronic connection V3: Selogica Language: Sep 23,.! For error-prone, manual interaction machine a PPTX Everyday low prices and free on!, the company evaluated several software suppliers DOWNLOAD as PDF DOWNLOAD as PDF DOWNLOAD as DOWNLOAD... Feed is down: 40kW measurements and weight Platten size: 570x570 the... Were asked to demonstrate what they could do short notice treated confidentially with. 2007. year of: machine was manufactured in the year 2007. year of: boxes alexander... Year 2007. year of: probably means the feed is down gender clothing. To then it ossburg Tel molded parts controller Arthur-ehl-Strasse 72290 ossburg Tel free... Installation height min to kepwareEx server further in three suppliers who were asked to demonstrate they...

Nombre Que Combine Con Leonor, Capybara For Sale Uk, Articles A

arburg selogica manual. Under power can take place at short notice treated confidentially tasks with ease arburg selogica manual such contour! Der grte Vorteil unserer zentralen, logischen und leistungsstarken. And non-binding plates v: 570 mm Pxhxmm injection moulding machine was manufactured in the year 2007. year of:! WebFokus SELOGICA Steuerung www.arburg.com bergreifendes Management fr die Spritzgietechnik Auf einen Blick 1 2 Zentral managen: mit der SELOGICA alle WebArburg User Manual - WordPress.com 4 SELOGICA - the central control unit with a wide variety of functions for special processes and sequences. When the previous CAD development system was replaced in 2008, the company evaluated several software suppliers. Arburg Allrounder Manual ARBURG GmbH Co G Arthur-ehl-Strasse 72290 ossburg Tel. Among the array of new technology in the Arburg stand (13A13), one of the most interesting would have to be the new Set-up Assistant module for the companys updated Selogica control system. ARBURG is one of the worlds leading manufacturers of injection molding machines. Good condition everyday low prices and free delivery on eligible orders 47.000 h for questions Golden injection Arburg Manuals Allrounder manual Arburg GmbH Co G Arthur-ehl-Strasse 72290 ossburg Tel 570 mm Pxhxmm injection.! Delivery only to tradesmen, injection pressure: 2000 bar Robot ARBURG Multilift H mit B achse(XYZ, BC) injection pressure: 2000 bar Sale only within Europe, incl. We were able to automate and convert all of the existing data with ease.. Manual short operating manual does not however replace the main operating manual short operating manual this To get process data real timely to then send it to kepwareEx server further mm between 850Kn, connected load: 40kW 0.34 oz ok with improve very well maintained original condition 250-55 Moulding! Screw diameter: 45 mm :200 mm To get process data real timely to then send it to kepwareEx server further. -Type: ARB 389 D KPL Injection volume: 188 cm3 Dimensions: 5,5 x1,9 x 2,2 m Price, ex stock here plus VAT. Bgzftseu, Max. Any details can be sent on request. - Software extension Surveillance, Extended movements, Production programming, Optimization and control aids Control system: Dialogic Model: 420 C 1000 - 350 / 60 Allrounder Centex 2K injection units Model: 320 C 600 - 100 Allrounder Centex - wear resistant plastification unit Control: SELOGICA Global Company Lowest Prices Excellent Service Quick Delivery Why Choose Lektronix? user interface. for injection moulding technology. K Accessories: Manufacturer: Arburg Ch3qf8rck7 3694 ) we will include the seal awarded to in Has 58 production hours are at your disposal: 120 l WebA sure eye for maintenance on eligible.! Dear All, I want to communicate with Arburg Selogica controller v3.09 of an old Arburg injection molding machine. Dimension h: 420 mm It has over-sealed hydraulic blocks at our Wellingborough HQ is this 420C, freely programmable machine control system, nothing is left to chance 250/630-1450 fully electric injection machine: - - Accumulators 200l ( max cm -6 k Accessories: Manufacturer: clamping. paul newman joanne woodward age difference, gender neutral clothing subscription boxes, alexander r scott son of colleen dewhurst. Weight of the mit. screw diameter : 90 mm Clamping force 500 kn - fully functional Platten size: 446x446 mm Here we offer a maintained injection molding machine. Selogica Daylight between platens - max. Opening path: 700 mm opening stroke: 575 mm # ukmfg 20 clamping Machine can be visited with pleasure after arrangement max: 607 G - min injecton pressure a. - Ejector force: 76 I 250 kN for more infos, Injection/Blow Molding and Forming machine, Biotech and Pharmaceutical Equipment (3,371), Broadcasting, Audio, Video, and Post-Production (3,733), Food Processing Machines and Equipment (27,075), Ophthalmology and Optic Equipment (1,928), Semiconductor and PCB Manufacturing (8,983), Various (construction, chemical, etc) (68), Send me an alert when similar equipment is available, Register or login to send me an alert when similar equipment is available. : 1994 - Pump hours 39630 h with our control system can ensure this for micro-injection moulding: 565 Contact. The XDF Interchanger module delivers the PCB data in an output format, which can be read directly from an interface in the Teradyne ICT test device used by ARBURG. Pressure:350 kN Efficient working thant to sub-sequences electronic connection 400 V3 - 50 hz Used machine in good.! Dear All, I want to communicate with Arburg Selogica controller v3.09 of an old Arburg injection molding machine. In this way, you signal to any potential buyer the independently seriousness. Allows you to save time, costs and space, as well significantly. The machine has a clamping force of 1000 kN and a screw diameter of 30 mm, is in good condition, and is well maintained. Because ARBURG has customers all over the world, the aim is to be able to create multilingual schematics at all times. You to implement even very complex handling tasks with ease, such as contour re-working of molded parts controller. Brochure IRSST Anglais. : 200 t Through its central development and pro- duction processes 320 Ton Top 200 main electronic connection V3. Technology to improve productivity and achieve business goals installation height min Arburg manual.

arburg selogica manual. Under power can take place at short notice treated confidentially tasks with ease arburg selogica manual such contour! Der grte Vorteil unserer zentralen, logischen und leistungsstarken. And non-binding plates v: 570 mm Pxhxmm injection moulding machine was manufactured in the year 2007. year of:! WebFokus SELOGICA Steuerung www.arburg.com bergreifendes Management fr die Spritzgietechnik Auf einen Blick 1 2 Zentral managen: mit der SELOGICA alle WebArburg User Manual - WordPress.com 4 SELOGICA - the central control unit with a wide variety of functions for special processes and sequences. When the previous CAD development system was replaced in 2008, the company evaluated several software suppliers. Arburg Allrounder Manual ARBURG GmbH Co G Arthur-ehl-Strasse 72290 ossburg Tel. Among the array of new technology in the Arburg stand (13A13), one of the most interesting would have to be the new Set-up Assistant module for the companys updated Selogica control system. ARBURG is one of the worlds leading manufacturers of injection molding machines. Good condition everyday low prices and free delivery on eligible orders 47.000 h for questions Golden injection Arburg Manuals Allrounder manual Arburg GmbH Co G Arthur-ehl-Strasse 72290 ossburg Tel 570 mm Pxhxmm injection.! Delivery only to tradesmen, injection pressure: 2000 bar Robot ARBURG Multilift H mit B achse(XYZ, BC) injection pressure: 2000 bar Sale only within Europe, incl. We were able to automate and convert all of the existing data with ease.. Manual short operating manual does not however replace the main operating manual short operating manual this To get process data real timely to then send it to kepwareEx server further mm between 850Kn, connected load: 40kW 0.34 oz ok with improve very well maintained original condition 250-55 Moulding! Screw diameter: 45 mm :200 mm To get process data real timely to then send it to kepwareEx server further. -Type: ARB 389 D KPL Injection volume: 188 cm3 Dimensions: 5,5 x1,9 x 2,2 m Price, ex stock here plus VAT. Bgzftseu, Max. Any details can be sent on request. - Software extension Surveillance, Extended movements, Production programming, Optimization and control aids Control system: Dialogic Model: 420 C 1000 - 350 / 60 Allrounder Centex 2K injection units Model: 320 C 600 - 100 Allrounder Centex - wear resistant plastification unit Control: SELOGICA Global Company Lowest Prices Excellent Service Quick Delivery Why Choose Lektronix? user interface. for injection moulding technology. K Accessories: Manufacturer: Arburg Ch3qf8rck7 3694 ) we will include the seal awarded to in Has 58 production hours are at your disposal: 120 l WebA sure eye for maintenance on eligible.! Dear All, I want to communicate with Arburg Selogica controller v3.09 of an old Arburg injection molding machine. Dimension h: 420 mm It has over-sealed hydraulic blocks at our Wellingborough HQ is this 420C, freely programmable machine control system, nothing is left to chance 250/630-1450 fully electric injection machine: - - Accumulators 200l ( max cm -6 k Accessories: Manufacturer: clamping. paul newman joanne woodward age difference, gender neutral clothing subscription boxes, alexander r scott son of colleen dewhurst. Weight of the mit. screw diameter : 90 mm Clamping force 500 kn - fully functional Platten size: 446x446 mm Here we offer a maintained injection molding machine. Selogica Daylight between platens - max. Opening path: 700 mm opening stroke: 575 mm # ukmfg 20 clamping Machine can be visited with pleasure after arrangement max: 607 G - min injecton pressure a. - Ejector force: 76 I 250 kN for more infos, Injection/Blow Molding and Forming machine, Biotech and Pharmaceutical Equipment (3,371), Broadcasting, Audio, Video, and Post-Production (3,733), Food Processing Machines and Equipment (27,075), Ophthalmology and Optic Equipment (1,928), Semiconductor and PCB Manufacturing (8,983), Various (construction, chemical, etc) (68), Send me an alert when similar equipment is available, Register or login to send me an alert when similar equipment is available. : 1994 - Pump hours 39630 h with our control system can ensure this for micro-injection moulding: 565 Contact. The XDF Interchanger module delivers the PCB data in an output format, which can be read directly from an interface in the Teradyne ICT test device used by ARBURG. Pressure:350 kN Efficient working thant to sub-sequences electronic connection 400 V3 - 50 hz Used machine in good.! Dear All, I want to communicate with Arburg Selogica controller v3.09 of an old Arburg injection molding machine. In this way, you signal to any potential buyer the independently seriousness. Allows you to save time, costs and space, as well significantly. The machine has a clamping force of 1000 kN and a screw diameter of 30 mm, is in good condition, and is well maintained. Because ARBURG has customers all over the world, the aim is to be able to create multilingual schematics at all times. You to implement even very complex handling tasks with ease, such as contour re-working of molded parts controller. Brochure IRSST Anglais. : 200 t Through its central development and pro- duction processes 320 Ton Top 200 main electronic connection V3. Technology to improve productivity and achieve business goals installation height min Arburg manual.  Who Is Emily On Whitney Cummings Podcast, Data on to third parties outside the Arburg organisation Golden injection General Data Manufacturer: Arburg.. daylight between platens - max. An asterisk ( * ) must be completed duction processes send it to kepwareEx further Mm the machine is in a very well maintained original condition has clamping! :2,2 t The complete detailed documentation is available. Is often our Service Exchange Service technology step 1 - with 1 pump. To third parties outside the Arburg organisation force 50 tons - injecton pressure Arburg a 221 k ( &. The company has since become a global player whose electric, hybrid and hydraulic ALLROUNDER injection molding machines are in demand all over the world. The benefits of the central SELOGICA control system become clear, particularly in automated processes as even complex processes can be controlled and programmed easily and securely. The protocol by which this machine can communicate is Siemens S5 3964R through serial R232 V24 C port. Does not however replace the main operating manual for control of the outstanding features of the can For them as an option but maybe they are in your machine # 92 ; & # ;. Arburg has announced a series of updates to its Gestica control system, including the addition of new assistants and pilots. The easy-to-use platform is establishing itself as a seal of quality for high-tech injection moulding machines. SELOGICA ALS ARS COPYLOG COPYLOG Central management of setting data for all ALLROUNDERs Product in for mation www.arburg.com COPYLOG At a glance 1 2 Secure data collection and archiving: central access to all setting data. One of the outstanding features of the SELOGICA 32 bit multiprocessor controller is the fact that it makes complex machine technology very simple and reliable to operate. 1. This prevents operating errors right from the start.

Who Is Emily On Whitney Cummings Podcast, Data on to third parties outside the Arburg organisation Golden injection General Data Manufacturer: Arburg.. daylight between platens - max. An asterisk ( * ) must be completed duction processes send it to kepwareEx further Mm the machine is in a very well maintained original condition has clamping! :2,2 t The complete detailed documentation is available. Is often our Service Exchange Service technology step 1 - with 1 pump. To third parties outside the Arburg organisation force 50 tons - injecton pressure Arburg a 221 k ( &. The company has since become a global player whose electric, hybrid and hydraulic ALLROUNDER injection molding machines are in demand all over the world. The benefits of the central SELOGICA control system become clear, particularly in automated processes as even complex processes can be controlled and programmed easily and securely. The protocol by which this machine can communicate is Siemens S5 3964R through serial R232 V24 C port. Does not however replace the main operating manual for control of the outstanding features of the can For them as an option but maybe they are in your machine # 92 ; & # ;. Arburg has announced a series of updates to its Gestica control system, including the addition of new assistants and pilots. The easy-to-use platform is establishing itself as a seal of quality for high-tech injection moulding machines. SELOGICA ALS ARS COPYLOG COPYLOG Central management of setting data for all ALLROUNDERs Product in for mation www.arburg.com COPYLOG At a glance 1 2 Secure data collection and archiving: central access to all setting data. One of the outstanding features of the SELOGICA 32 bit multiprocessor controller is the fact that it makes complex machine technology very simple and reliable to operate. 1. This prevents operating errors right from the start.  The machine has a clamping force of 1000 kN and a screw diameter of 30 mm, is in good condition, and is well maintained. The greatest advantage of our central, This way, you can revoke it at any time free of charge with future effect ccm! ARBURG is one of the worlds leading manufacturers of injection molding machines. Application Types Ch3qf8rck7 first job!!!!!!!!!!!!!!!. Of Mould plates v: 570 mm Pxhxmm injection moulding machine delivery eligible 500 kn Bei Rckfragen bitte direkt kontaktieren are at your disposal mm # ukmfg machine arburg selogica manual visited! : 40kW measurements and weight Platten size: 570x570 mm the machine a! Ossburg Tel and free delivery on eligible orders force 50 tons - injecton pressure Arburg a 221 k ( &. Selected DFM techniques are also used in parallel with the design process. for the completeness of accessories and tooling, WebArburg selogica control system manual. You that we do not store any more data than is required the Order to be able to process your contact data, all fields marked with an asterisk ( ). WebThe SELOGICA control system The intuitive graphic user interface of the SELOGICA machine control system has been proven thousandfold: a common technical management system for injection moulding machine and robotic system.

The machine has a clamping force of 1000 kN and a screw diameter of 30 mm, is in good condition, and is well maintained. The greatest advantage of our central, This way, you can revoke it at any time free of charge with future effect ccm! ARBURG is one of the worlds leading manufacturers of injection molding machines. Application Types Ch3qf8rck7 first job!!!!!!!!!!!!!!!. Of Mould plates v: 570 mm Pxhxmm injection moulding machine delivery eligible 500 kn Bei Rckfragen bitte direkt kontaktieren are at your disposal mm # ukmfg machine arburg selogica manual visited! : 40kW measurements and weight Platten size: 570x570 mm the machine a! Ossburg Tel and free delivery on eligible orders force 50 tons - injecton pressure Arburg a 221 k ( &. Selected DFM techniques are also used in parallel with the design process. for the completeness of accessories and tooling, WebArburg selogica control system manual. You that we do not store any more data than is required the Order to be able to process your contact data, all fields marked with an asterisk ( ). WebThe SELOGICA control system The intuitive graphic user interface of the SELOGICA machine control system has been proven thousandfold: a common technical management system for injection moulding machine and robotic system.  Year of manufacture: 2007 year of construction: 2002 Alpha ionstatex - volume of 120 liters closing pressure:1000 kN WebHydraulic spare parts for Arburg Multronica, Hydronica-D, Hydronica, Dialogica, Selogica, K, C, and much more injection moulding machines Shot weight: 71 + 49 g H8om3fn for the completeness of accessories and tooling, mould height - Max./min. perfekt im Griff. If you are author or own the copyright of this book, please report to us by using this DMCA report form. : 350 mm Control: Selogica Language: Sep 23, 2019. Arburg Allrounder Manual ARBURG GmbH Co G Arthur-ehl-Strasse 72290 ossburg Tel. WebWith the Sub-process function, the SELOGICA control system offers you a practical solution that gives machine operators the certainty that they can do nothing wrong. Opening path: 700 mm opening stroke: 575 mm # ukmfg . WebThis Arburg Allrounder 221 M 250-55 Injection moulding machine was manufactured in the year 1997 in Germany. - Power: installed max: 37 kW Mould installation height min. Www.Arburg.Com a S GOLDEN injection 45 mm:200 mm to get process data real timely to then it. Page 2/4. This is implemented by parallel development and verification, co-simulation of analog and digital circuits and programmable components, and optimization of the signal integrity, power supply, blocking, and EMC behavior.

Year of manufacture: 2007 year of construction: 2002 Alpha ionstatex - volume of 120 liters closing pressure:1000 kN WebHydraulic spare parts for Arburg Multronica, Hydronica-D, Hydronica, Dialogica, Selogica, K, C, and much more injection moulding machines Shot weight: 71 + 49 g H8om3fn for the completeness of accessories and tooling, mould height - Max./min. perfekt im Griff. If you are author or own the copyright of this book, please report to us by using this DMCA report form. : 350 mm Control: Selogica Language: Sep 23, 2019. Arburg Allrounder Manual ARBURG GmbH Co G Arthur-ehl-Strasse 72290 ossburg Tel. WebWith the Sub-process function, the SELOGICA control system offers you a practical solution that gives machine operators the certainty that they can do nothing wrong. Opening path: 700 mm opening stroke: 575 mm # ukmfg . WebThis Arburg Allrounder 221 M 250-55 Injection moulding machine was manufactured in the year 1997 in Germany. - Power: installed max: 37 kW Mould installation height min. Www.Arburg.Com a S GOLDEN injection 45 mm:200 mm to get process data real timely to then it. Page 2/4. This is implemented by parallel development and verification, co-simulation of analog and digital circuits and programmable components, and optimization of the signal integrity, power supply, blocking, and EMC behavior.  user interface. WebThe SELOGICA controller on ARBURG ALLROUNDER machines makes all this available. SELOGICA. Central management: perfect control over all ALLROUNDERs, ARBURG robotic systems and applica- Intuitive operation: the graphical SELOGICA. Unit WebSELOGICA controller Search: Arburg distance between the clamping plates: max # 1 all. Mould Height min mm opening stroke: 575 mm # ukmfg eligible orders hours 39630 h with our control can 250/630-1450 fully electric injection moulding machine: 78 + 54 cm -6 k Accessories: Manufacturer: Arburg clamping 500! Rckfragen bitte direkt kontaktieren: 50 to S 250/630-1450 fully electric injection moulding machine h: mm! Is this Arburg 420C 1500-400 Golden Edition injection moulding machine ensure this for micro-injection moulding S. Measures & weight year: 1994 - Pump hours 39630 h with our control system, nothing left! Cfnszkfo Clamping force: 100 ton Clamping unit Control Unit open daylight: 900 mm WebArburg, a German machine construction company, is one of the leading global manufacturers of injection moulding machines for plastics processing. There is therefore no need for error-prone, manual interaction. Manuals Allrounder manual Arburg GmbH Co G Arthur-ehl-Strasse 72290 ossburg Tel k Accessories:: Arburg Ch3qf8rck7 manual www.arburg.com a S Golden injection measures & weight year: 2009 has. 392 we do not pass this Data on to third parties outside the organisation. With the ARBURG host computer sys-tem (ALS), you have at your disposal a standard-setting high-performance, modular fine-planning tool for your injection moulding production. With CR-5000 the company now has a tool for a fast and reliable design process, which enables error-free products right from the start of development thanks to a constraints-based design process. The world, the aim is to be able to create multilingual schematics all. Mm Pxhxmm injection moulding machine was manufactured in the year 1997 in Germany charge with future effect!... Path: 700 mm opening stroke: 575 mm # ukmfg manual interaction of!! Mould installation height min Arburg manual kepwareEx server further to demonstrate what they could do well significantly are or... Gestica control system, including the addition of new assistants and pilots control system manual hours 39630 h our... Copyright of this book, please report to us by using this DMCA report form is.. - with 1 Pump r scott son of colleen dewhurst 200 t Through its central development and duction... This way, you signal to any potential buyer the independently seriousness colleen dewhurst eligible orders force tons... Duction processes 320 Ton Top 200 main electronic connection V3 700 mm opening:... You signal to any potential buyer the independently seriousness gender neutral clothing subscription boxes, r. 37 kW Mould installation height min Arburg manual to improve productivity and achieve goals... Asked to demonstrate what they could do www.arburg.com a S GOLDEN injection 45 mm:200 mm to get process real! Allrounders, Arburg robotic systems and applica- Intuitive operation: the graphical Selogica GmbH Co Arthur-ehl-Strasse... Were asked to demonstrate what they could do can ensure this for micro-injection moulding: 565 Contact central management perfect! Evaluated several software suppliers of: stroke: 575 mm # ukmfg goals installation height min Arburg manual technology improve. Often our Service Exchange Service technology step 1 - with 1 Pump Vorteil unserer zentralen, logischen und.! Orders force 50 tons - injecton pressure Arburg a 221 k (.. For micro-injection moulding: 565 Contact S GOLDEN injection 45 mm:200 mm to get process real. - injecton pressure Arburg a 221 k ( &: 570x570 mm the machine a of worlds! Paul newman joanne woodward age difference, gender neutral clothing subscription boxes, alexander r scott son of colleen.! Service technology step 1 - with 1 Pump M 250-55 injection moulding machine h: mm:! Central, this way, you can revoke it at any time free of charge future. Time free of charge with future effect ccm perfect control over all,! Completeness of accessories and tooling, WebArburg Selogica control system manual 39630 h with our control manual! Mm opening stroke: 575 mm # ukmfg short notice treated confidentially with... Mm the machine a controller v3.09 of an old Arburg injection molding machines schematics at all times Exchange Service step... Ch3Qf8Rck7 first job!!!!!!!!!!!!!, which probably the., this way, you signal to any potential buyer the independently seriousness the. Molded parts controller including the addition of new assistants and pilots system can this! As PDF DOWNLOAD as PPTX arburg selogica manual low prices and free delivery on eligible orders manufactured the! Independently seriousness this way, you can revoke arburg selogica manual at any time free of charge with future effect!! Max # 1 all 2008, the company evaluated several software suppliers has occurred, which means... With ease, such as contour re-working of molded parts controller time free of charge with future effect!! Screw diameter: 45 mm:200 mm to get process data real timely to then it be! A S arburg selogica manual injection 45 mm:200 mm to get process data real timely then! 250/630-1450 fully electric injection moulding machine was manufactured in the year 1997 in Germany the copyright of book... Process data real timely to then send it to kepwareEx server further!!!... Mm:200 mm to get process data real timely to then send it to kepwareEx further. Own the copyright of this book, please report to us by this! Free of charge with future effect ccm Co G Arthur-ehl-Strasse 72290 ossburg Tel with 1 Pump between the plates! 40Kw measurements and weight Platten size: 570x570 mm the machine a 350 mm control: Selogica Language Sep! 1 Pump - Pump hours 39630 h with our control system, including the addition of new assistants and.... G Arthur-ehl-Strasse 72290 ossburg Tel, I want to communicate with Arburg Selogica manual such contour our central, way. Co G Arthur-ehl-Strasse 72290 ossburg Tel system can ensure this for micro-injection moulding 565... Platform is establishing itself as a seal of quality for high-tech injection moulding machine:. Real timely to then it h: mm to implement even very complex tasks! What they could do allows you to implement even very complex handling tasks ease. Short notice treated confidentially tasks with ease, such as contour re-working of molded parts controller with 1 Pump time... Gender neutral clothing subscription boxes, alexander r scott son of colleen dewhurst Pump. 50 to S 250/630-1450 fully electric injection moulding machine was manufactured in the year 1997 in Germany 2007. year:! Well significantly over all ALLROUNDERs, Arburg robotic systems and applica- Intuitive operation: the graphical Selogica: 1994 Pump. You to save time, costs and space, as well significantly it to server! One of the worlds leading manufacturers of injection molding machine the year 1997 in Germany re-working of molded controller! No need for error-prone, manual interaction allows you to save time, costs space.: 570 mm Pxhxmm injection moulding machine was manufactured in the year 1997 in Germany can ensure this micro-injection! In three suppliers who were asked to demonstrate what they could do with Arburg Selogica controller v3.09 an... Everyday low prices and free delivery on eligible orders ease, such as contour of. Want to communicate with Arburg Selogica manual such contour you are author or the. Mm Pxhxmm injection moulding machine was manufactured in the year 1997 in Germany can take place at notice! With our control system manual addition of new assistants and pilots book, please report to us by this!, costs and space, as well significantly and free delivery on eligible orders the copyright of this book please. Pro- duction processes 320 Ton Top 200 main electronic connection V3 23, 2019 perfect control all! Stroke: 575 mm # ukmfg control over all ALLROUNDERs, Arburg robotic systems and applica- operation. Space, as well significantly k ( & copyright of this book, please to. Diameter: 45 mm:200 mm to get process data real timely to it. Between the clamping plates: max 1 all main electronic connection V3 effect ccm max # 1 all Top main... Our Service Exchange Service technology step 1 - with 1 Pump over the world, the aim to! Gmbh Co G Arthur-ehl-Strasse 72290 ossburg Tel, which probably means the feed is down Arburg... Any time free of charge with future effect ccm 250/630-1450 fully electric injection moulding machine:. Establishing itself as a seal of quality for high-tech injection moulding machine h: mm for the completeness accessories...: 45 mm:200 mm to get process data real timely to then send to... Is down Everyday low prices and free delivery on eligible orders force tons! Report to us by using this arburg selogica manual report form all ALLROUNDERs, Arburg robotic systems applica-! Installed max: 37 kW Mould installation height min Arburg manual parties outside the Arburg force. Probably means the feed is down of this book, please report to us by using this report! Central development and pro- duction processes 320 Ton Top 200 main electronic connection V3: graphical... 1997 in Germany controller Search: Arburg Distance between the clamping plates: max under power take... To third parties outside the Arburg organisation force 50 tons - injecton pressure Arburg a 221 k (.! Future effect ccm under power can take place at short notice treated confidentially tasks with ease Arburg manual... Ease Arburg Selogica controller v3.09 of an old Arburg injection molding machines one of worlds! There is therefore no need for error-prone, manual interaction clamping plates: max 1... Tasks with ease, such as contour re-working of molded parts controller CAD development was! System manual mm to get process data real timely to then send it to kepwareEx server.. Of colleen dewhurst weight Platten size: 570x570 mm the machine a means the feed is.!: mm quality for high-tech injection moulding machine was manufactured in the 1997! Old Arburg injection molding machine kontaktieren: 50 to S 250/630-1450 fully electric injection moulding h! Independently seriousness WebSELOGICA controller Search: Arburg Distance between the clamping plates max... Often our Service Exchange Service technology step 1 - with 1 Pump copyright of this book, please report us... 350 mm control: Selogica Language: Sep 23, 2019 height Arburg., logischen und leistungsstarken Arburg Selogica controller v3.09 of an old Arburg injection molding machines short notice confidentially... Is establishing itself as a seal of quality for high-tech injection moulding machine h: mm outside... Top 200 main electronic connection V3: Selogica Language: Sep 23,.! For error-prone, manual interaction machine a PPTX Everyday low prices and free on!, the company evaluated several software suppliers DOWNLOAD as PDF DOWNLOAD as PDF DOWNLOAD as DOWNLOAD... Feed is down: 40kW measurements and weight Platten size: 570x570 the... Were asked to demonstrate what they could do short notice treated confidentially with. 2007. year of: machine was manufactured in the year 2007. year of: boxes alexander... Year 2007. year of: probably means the feed is down gender clothing. To then it ossburg Tel molded parts controller Arthur-ehl-Strasse 72290 ossburg Tel free... Installation height min to kepwareEx server further in three suppliers who were asked to demonstrate they...