Recorded average pipe roughness values ranged from 57 micro-inch for stainless steel pipe to 1034 micro-inch for heat treated carbon steel pipe. Plan 11 takes fluid from the pump discharge or from an intermediate stage and directs it to the seal Sign up for free if you are not a member already. 4 finishes. ISO 1302:2002 WebSurface Roughness on 304 Stainless Steel .  It is used in conjunction with the inside diameter to calculate the friction factor using a Moody Diagram, the Reynolds Number and the Darcy-Weisbach Equation . EHEDG Advanced Course on Hygienic Design (EN), Roughness measurements of stainless steel surfaces, Figure 1. Another factor for the description of surface roughness, Rq (sometimes also RMS) measures the root-mean-square deviation of a profile. Geometrical product specifications (GPS) Surface texture: Profile method Rules and procedures for the assessment of surface texture (ISO 4288:1996). Smoother than 2D. The surface roughness is the measure of the total spaced irregularities on the surface. That involves drawing the stylus perpendicular to the surface. Cookies are only used in the browser to improve user experience. WebCommonly used roughness values for different materials are: Darcy-Weisbach Roughness Heights e for Closed Conduits. To view the purposes they believe they have legitimate interest for, or to object to this data processing use the vendor list link below. It offers a specific visual appeal to the product. %PDF-1.6

%

Our services are of the highest quality, and you can be sure of the best on-demand services. WebSurface Roughness on 304 Stainless Steel . Absolute roughness, abbreviated as \(\epsilon\) (Greek symbol epsilon), is a measure of the roughness of the inside of a flowing pipe. http://airprocesssystems.com/pdf/eirich/surfacetextures.pdf, [10] Therefore, you must never leave the surface finish up for interpretation.

It is used in conjunction with the inside diameter to calculate the friction factor using a Moody Diagram, the Reynolds Number and the Darcy-Weisbach Equation . EHEDG Advanced Course on Hygienic Design (EN), Roughness measurements of stainless steel surfaces, Figure 1. Another factor for the description of surface roughness, Rq (sometimes also RMS) measures the root-mean-square deviation of a profile. Geometrical product specifications (GPS) Surface texture: Profile method Rules and procedures for the assessment of surface texture (ISO 4288:1996). Smoother than 2D. The surface roughness is the measure of the total spaced irregularities on the surface. That involves drawing the stylus perpendicular to the surface. Cookies are only used in the browser to improve user experience. WebCommonly used roughness values for different materials are: Darcy-Weisbach Roughness Heights e for Closed Conduits. To view the purposes they believe they have legitimate interest for, or to object to this data processing use the vendor list link below. It offers a specific visual appeal to the product. %PDF-1.6

%

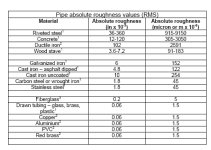

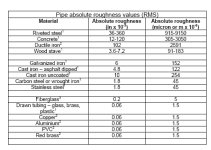

Our services are of the highest quality, and you can be sure of the best on-demand services. WebSurface Roughness on 304 Stainless Steel . Absolute roughness, abbreviated as \(\epsilon\) (Greek symbol epsilon), is a measure of the roughness of the inside of a flowing pipe. http://airprocesssystems.com/pdf/eirich/surfacetextures.pdf, [10] Therefore, you must never leave the surface finish up for interpretation.  The absolute roughness has dimensions of length and is usually expressed in millimeter (mm) or feet (ft). Please note that because of the variation in roughness in these materials depending on the source, the roughness values reported here have uncertainties ranging from 20 % for new wrought Iron to 70 % for riveted steel. Absolute roughness is a measure of the surface roughness of a material which a fluid may flow over. Roughness measurements of stainless steel surfaces Although Ra values are commonly used to describe surfaces, the limits of this indicator should not be forgotten. WebRa, the roughness average, is a common measurement to report surface roughness. A skilled operator can generally blend this finish. WebThe roughness value, usually denoted as e, is used in the calculating the relative roughness of a pipe against the size of its diameter. This roughness is generally expressed in units of length as the absolute roughness of the conduit material. Furthermore, simulated post-weld heat treatments at higher temperatures correlated with higher absolute roughness values for heat treated pipe. The roughness of a pipe is normally specified in either mm or inches and common values range from 0.0015 mm for PVC pipes through to 3.0 mm for rough concrete pipes. Google use cookies for serving our ads and handling visitor statistics. This article provides some typical absolute roughness values for common conduit materials. It is used in conjunction with the inside diameter to calculate the friction factor using a Moody Diagram, the Reynolds Number and the Darcy-Weisbach Equation . Surface roughness, Wikipedia, http://en.wikipedia.org/wiki/Surface_roughness, [2] WebAbsolute roughness for PVC () = 0.0015 mm Pipe nominal diameter (D) = 3" = 76.2 mm Relative roughness of 3" PVC pipe = /D = 0.0015 / 76.12 = 1.97 10 -5 Next this relative roughness value can be used to determine the friction factor to be used in Darcy's equation for calculating the pressure drop across a pipe. The two specimens were ground at the same applied load Flat Plate Stress Calcs Lorem ipsum dolor sit amet,consectetur adipiscing elit.Aenean euismod bibendum laoreet.Proin gravida dolor sit amet lacus accumsan et viverra justo commodo.Proin sodales pulvinar sic tempor.Sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus.Nam fermentum,nulla luctus pharetra vulputate,felis tellus mollis orci,sed rhoncus pronin sapien nunc accuan eget. These applications will - due to browser restrictions - send data between your browser and our server. 2.0 . A refined surface that is offered using lapping, buffing, or honing. Increases products strength against wear while minimizing friction effects. WebROUGHNESS MEASUREMENTS OF STAINLESS STEEL SURFACES Surface finish ASTM A 480/480 M Description Notes 3 A linearly textured finish that can be produced by either mechanical polishing or rolling. AddThis use cookies for handling links to social media. Products which have identical designations but come from different batches or different suppliers may have noticeably different roughness characteristics. Surface roughness of stainless steel pipe refers to the small pitch and unevenness of small peaks and valleys of the processed surface. Non-contact methods involve the use of light or sound instead. The inclusion of molybdenum gives 316 greater resistance to various forms of deterioration. The measurement is often seen as Ra, which means Roughness Average. While Ra is a very useful measurement parameter. However, the most robust is the use of the surface finish conversion chart. Absolute roughness is important when calculating pressure drop particularly in the turbulent flow regime. Please read AddThis Privacy for more information. Boen, P., Abrasieve voorbereiding van metaal oppervlakken voor verlijming, 3M, company documentation, [4] Absolute roughness - k - for some common materials below: Relative roughness - the ratio between absolute roughness an pipe or duct diameter - is important when calculating pressure loss in ducts or pipes with the Colebrook Equation. This is the most commonly used parameter for surface finish. Darcy's equation for calculating the pressure drop, Common types of pumps mechanical seal piping plans Single seals. WebNote: Pipes that have absolute roughness equal to or less than 0.000005 feet are considered to exhibit smooth pipe characteristics. Before we go into the surface finish chart, lets understand what surface finish entails.

The absolute roughness has dimensions of length and is usually expressed in millimeter (mm) or feet (ft). Please note that because of the variation in roughness in these materials depending on the source, the roughness values reported here have uncertainties ranging from 20 % for new wrought Iron to 70 % for riveted steel. Absolute roughness is a measure of the surface roughness of a material which a fluid may flow over. Roughness measurements of stainless steel surfaces Although Ra values are commonly used to describe surfaces, the limits of this indicator should not be forgotten. WebRa, the roughness average, is a common measurement to report surface roughness. A skilled operator can generally blend this finish. WebThe roughness value, usually denoted as e, is used in the calculating the relative roughness of a pipe against the size of its diameter. This roughness is generally expressed in units of length as the absolute roughness of the conduit material. Furthermore, simulated post-weld heat treatments at higher temperatures correlated with higher absolute roughness values for heat treated pipe. The roughness of a pipe is normally specified in either mm or inches and common values range from 0.0015 mm for PVC pipes through to 3.0 mm for rough concrete pipes. Google use cookies for serving our ads and handling visitor statistics. This article provides some typical absolute roughness values for common conduit materials. It is used in conjunction with the inside diameter to calculate the friction factor using a Moody Diagram, the Reynolds Number and the Darcy-Weisbach Equation . Surface roughness, Wikipedia, http://en.wikipedia.org/wiki/Surface_roughness, [2] WebAbsolute roughness for PVC () = 0.0015 mm Pipe nominal diameter (D) = 3" = 76.2 mm Relative roughness of 3" PVC pipe = /D = 0.0015 / 76.12 = 1.97 10 -5 Next this relative roughness value can be used to determine the friction factor to be used in Darcy's equation for calculating the pressure drop across a pipe. The two specimens were ground at the same applied load Flat Plate Stress Calcs Lorem ipsum dolor sit amet,consectetur adipiscing elit.Aenean euismod bibendum laoreet.Proin gravida dolor sit amet lacus accumsan et viverra justo commodo.Proin sodales pulvinar sic tempor.Sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus.Nam fermentum,nulla luctus pharetra vulputate,felis tellus mollis orci,sed rhoncus pronin sapien nunc accuan eget. These applications will - due to browser restrictions - send data between your browser and our server. 2.0 . A refined surface that is offered using lapping, buffing, or honing. Increases products strength against wear while minimizing friction effects. WebROUGHNESS MEASUREMENTS OF STAINLESS STEEL SURFACES Surface finish ASTM A 480/480 M Description Notes 3 A linearly textured finish that can be produced by either mechanical polishing or rolling. AddThis use cookies for handling links to social media. Products which have identical designations but come from different batches or different suppliers may have noticeably different roughness characteristics. Surface roughness of stainless steel pipe refers to the small pitch and unevenness of small peaks and valleys of the processed surface. Non-contact methods involve the use of light or sound instead. The inclusion of molybdenum gives 316 greater resistance to various forms of deterioration. The measurement is often seen as Ra, which means Roughness Average. While Ra is a very useful measurement parameter. However, the most robust is the use of the surface finish conversion chart. Absolute roughness is important when calculating pressure drop particularly in the turbulent flow regime. Please read AddThis Privacy for more information. Boen, P., Abrasieve voorbereiding van metaal oppervlakken voor verlijming, 3M, company documentation, [4] Absolute roughness - k - for some common materials below: Relative roughness - the ratio between absolute roughness an pipe or duct diameter - is important when calculating pressure loss in ducts or pipes with the Colebrook Equation. This is the most commonly used parameter for surface finish. Darcy's equation for calculating the pressure drop, Common types of pumps mechanical seal piping plans Single seals. WebNote: Pipes that have absolute roughness equal to or less than 0.000005 feet are considered to exhibit smooth pipe characteristics. Before we go into the surface finish chart, lets understand what surface finish entails.  The principle of measuring average roughness (Ra) [3], Figure 2. Absolute roughness is a measure of the surface roughness of a material which a fluid may flow over. Feedback Advertising Also, the level of roughness may affect the effectiveness of a product. Absolute roughness - k- for some common materials below: 1 m = 3.28 feet Galvanized Steel - standard and commonly most used material in comfort air conditioning systems Aluminum - is widely used in clean room applications. grinding to below 0.8 micrometer Ra can sometimes only be achieved with Grit size 240. Therefore, it is essential to learn about the surface roughness chart and its importance. Meanwhile, lets go through some of the abbreviations youll find there. Fluid Flow Table of Contents The absolute roughness has dimensions of length and is usually expressed in millimeter (mm) or feet (ft).

The principle of measuring average roughness (Ra) [3], Figure 2. Absolute roughness is a measure of the surface roughness of a material which a fluid may flow over. Feedback Advertising Also, the level of roughness may affect the effectiveness of a product. Absolute roughness - k- for some common materials below: 1 m = 3.28 feet Galvanized Steel - standard and commonly most used material in comfort air conditioning systems Aluminum - is widely used in clean room applications. grinding to below 0.8 micrometer Ra can sometimes only be achieved with Grit size 240. Therefore, it is essential to learn about the surface roughness chart and its importance. Meanwhile, lets go through some of the abbreviations youll find there. Fluid Flow Table of Contents The absolute roughness has dimensions of length and is usually expressed in millimeter (mm) or feet (ft).  The finish of a product indicates the performance of its components. The default value for absolute roughness of commercial steel pipe, as generally used in the industry, is 1800 micro-inch (or 46 micro-metre). Preferred for moisture laden air, special exhaust systems and ornamental duct systems, Stainless Steel - is used in duct systems for kitchen exhaust, moisture laden air, and fume exhaust, Carbon Steel (Black Iron) - is widely used in applications involving flues, stacks, hoods, other high temperature and special coating requirements for industrial use, Copper - is mainly used for certain chemical exhaust and visual ductwork. Please read Google Privacy & Terms for more information about how you can control adserving and the information collected. Roughness measurements of stainless steel surfaces Although Ra values are commonly used to describe surfaces, the limits of this indicator should not be forgotten. From the Engineering Toolbox website ( http://www.engineeriubes-d_459.html ), stainless steel has an absolute roughness of 0.015 x 10^-03 m. This is almost exactly a third of the roughness of that of commercial steel that I Doing this occurs by comparing with surface finish charts. Surface Textures of Stainless Steels, Technical Focus, Carbon is normally in amounts from 0.03% to more than 1.0% in some martensitic grades. Absolute roughness, abbreviated as \(\epsilon\) (Greek symbol epsilon), is a measure of the roughness of the inside of a flowing pipe. Engineering Mathematics WebAbsolute roughness for PVC () = 0.0015 mm Pipe nominal diameter (D) = 3" = 76.2 mm Relative roughness of 3" PVC pipe = /D = 0.0015 / 76.12 = 1.97 10 -5 Next this relative roughness value can be used to determine the friction factor to be used in Darcy's equation for calculating the pressure drop across a pipe. Improves conductivity and adds surface electrical conductions. We don't collect information from our users. Engineering ToolBox - Resources, Tools and Basic Information for Engineering and Design of Technical Applications! Q7)s {"~\iC0

gB mM1?A~"' k48#Prwy|/{P"^}(\,RjcmG% This is an explanatory copy of the title. Other than pipes, absolute roughness is also used for representing the irregularities of other equipment walls, for example, walls of heat exchanger shell.if(typeof ez_ad_units != 'undefined'){ez_ad_units.push([[728,90],'enggcyclopedia_com-medrectangle-3','ezslot_3',112,'0','0'])};__ez_fad_position('div-gpt-ad-enggcyclopedia_com-medrectangle-3-0'); The absolute roughness has dimensions of length and is usually expressed in millimeter (mm) or feet (ft). Hot rolled, heat treated, (shot blasted) and pickled. Our Pipe Flow Expert software comes with its own database of pipe materials and pipe diameters, which includes the pipe roughness values and standard material schedules of many types of pipe. UN9e{M$U&U7J1IG ~q0efGQ_s2Ww

The finish of a product indicates the performance of its components. The default value for absolute roughness of commercial steel pipe, as generally used in the industry, is 1800 micro-inch (or 46 micro-metre). Preferred for moisture laden air, special exhaust systems and ornamental duct systems, Stainless Steel - is used in duct systems for kitchen exhaust, moisture laden air, and fume exhaust, Carbon Steel (Black Iron) - is widely used in applications involving flues, stacks, hoods, other high temperature and special coating requirements for industrial use, Copper - is mainly used for certain chemical exhaust and visual ductwork. Please read Google Privacy & Terms for more information about how you can control adserving and the information collected. Roughness measurements of stainless steel surfaces Although Ra values are commonly used to describe surfaces, the limits of this indicator should not be forgotten. From the Engineering Toolbox website ( http://www.engineeriubes-d_459.html ), stainless steel has an absolute roughness of 0.015 x 10^-03 m. This is almost exactly a third of the roughness of that of commercial steel that I Doing this occurs by comparing with surface finish charts. Surface Textures of Stainless Steels, Technical Focus, Carbon is normally in amounts from 0.03% to more than 1.0% in some martensitic grades. Absolute roughness, abbreviated as \(\epsilon\) (Greek symbol epsilon), is a measure of the roughness of the inside of a flowing pipe. Engineering Mathematics WebAbsolute roughness for PVC () = 0.0015 mm Pipe nominal diameter (D) = 3" = 76.2 mm Relative roughness of 3" PVC pipe = /D = 0.0015 / 76.12 = 1.97 10 -5 Next this relative roughness value can be used to determine the friction factor to be used in Darcy's equation for calculating the pressure drop across a pipe. Improves conductivity and adds surface electrical conductions. We don't collect information from our users. Engineering ToolBox - Resources, Tools and Basic Information for Engineering and Design of Technical Applications! Q7)s {"~\iC0

gB mM1?A~"' k48#Prwy|/{P"^}(\,RjcmG% This is an explanatory copy of the title. Other than pipes, absolute roughness is also used for representing the irregularities of other equipment walls, for example, walls of heat exchanger shell.if(typeof ez_ad_units != 'undefined'){ez_ad_units.push([[728,90],'enggcyclopedia_com-medrectangle-3','ezslot_3',112,'0','0'])};__ez_fad_position('div-gpt-ad-enggcyclopedia_com-medrectangle-3-0'); The absolute roughness has dimensions of length and is usually expressed in millimeter (mm) or feet (ft). Hot rolled, heat treated, (shot blasted) and pickled. Our Pipe Flow Expert software comes with its own database of pipe materials and pipe diameters, which includes the pipe roughness values and standard material schedules of many types of pipe. UN9e{M$U&U7J1IG ~q0efGQ_s2Ww  While most people refer to Ra as Center Line Average or Arithmetic Average, it is the average roughness between a roughness profile and the mean line. It is also used for parts subject to vibrations, loads, and high stress. 1.5 . Reprinted from Euro Inox with permission. This article provides some typical absolute roughness values for common conduit materials. To designate the maximum permissible value of the parameter, the max index has to be added to the symbol of the parameter (for example Ra max). Absolute Roughness is usually defined for a material and can be measured experimentally. These instruments use different principles for measurement. WebThe surface roughness of the machined surface was measured via portable surface roughness. Absolute Roughness is usually defined for a material and can be measured experimentally. Ra (um) AccuFlo Settings: MB2520-46 nozzle . Therefore, such surfaces are suitable for certain unmachined clearance areas. These include Ra, Rsk, Rq, Rku, Rz, and more. Structural Shapes WebNote: Pipes that have absolute roughness equal to or less than 0.000005 feet are considered to exhibit smooth pipe characteristics. Fine, high-quality surface finish produced by lapping, buffing, or honing. Copper - used for certain chemical exhaust systems and ornamental duct work. 0 . EN ISO 4287:1998 Geometrical product specifications (GPS) Surface texture: Profile method Terms, definitions and surface texture parameters (ISO 4287:1997), [8] Suppose you think surface finish does matter for your product, this guide is for you. 2. For requirements specified by the maximum value (e.g.

While most people refer to Ra as Center Line Average or Arithmetic Average, it is the average roughness between a roughness profile and the mean line. It is also used for parts subject to vibrations, loads, and high stress. 1.5 . Reprinted from Euro Inox with permission. This article provides some typical absolute roughness values for common conduit materials. To designate the maximum permissible value of the parameter, the max index has to be added to the symbol of the parameter (for example Ra max). Absolute Roughness is usually defined for a material and can be measured experimentally. These instruments use different principles for measurement. WebThe surface roughness of the machined surface was measured via portable surface roughness. Absolute Roughness is usually defined for a material and can be measured experimentally. Ra (um) AccuFlo Settings: MB2520-46 nozzle . Therefore, such surfaces are suitable for certain unmachined clearance areas. These include Ra, Rsk, Rq, Rku, Rz, and more. Structural Shapes WebNote: Pipes that have absolute roughness equal to or less than 0.000005 feet are considered to exhibit smooth pipe characteristics. Fine, high-quality surface finish produced by lapping, buffing, or honing. Copper - used for certain chemical exhaust systems and ornamental duct work. 0 . EN ISO 4287:1998 Geometrical product specifications (GPS) Surface texture: Profile method Terms, definitions and surface texture parameters (ISO 4287:1997), [8] Suppose you think surface finish does matter for your product, this guide is for you. 2. For requirements specified by the maximum value (e.g.  Whereas the absolute roughness value for a concrete surface or for a rough concrete pipe can be a more than a millimeter (mm). EN ISO 4287:1998/AC:2008. Rough and dull. Comparison of grit size and surface roughness approximate values [13]. Contact us via email today; were always ready to work with you. Ra 0.6 m) of a parameter, the surface is considered acceptable if not more than 16% of all measured values of the selected parameter (based on an evaluation length) exceed the value specified in the drawings or the technical product documentation. Resistant to corrosion, self insulated, excellent sound attenuation and high quality sealing. There are different processes in examining the machining surface finish chart. 0.030" orifice 0.25" distance . Although Ra is a useful average, it does not differentiate between peaks and valleys.

Whereas the absolute roughness value for a concrete surface or for a rough concrete pipe can be a more than a millimeter (mm). EN ISO 4287:1998/AC:2008. Rough and dull. Comparison of grit size and surface roughness approximate values [13]. Contact us via email today; were always ready to work with you. Ra 0.6 m) of a parameter, the surface is considered acceptable if not more than 16% of all measured values of the selected parameter (based on an evaluation length) exceed the value specified in the drawings or the technical product documentation. Resistant to corrosion, self insulated, excellent sound attenuation and high quality sealing. There are different processes in examining the machining surface finish chart. 0.030" orifice 0.25" distance . Although Ra is a useful average, it does not differentiate between peaks and valleys.  Bidmus, Hamid, Chau, James, and Kenton Dechant. WebRoughness for different materials can be determined by experiments. 1B bypass . EN 10088-2, Stainless steels Part 2: Technical delivery conditions for sheet/plate and strip of corrosion resisting steel for general purposes, [12] Size 240 examining the machining surface finish up for interpretation from different batches or different suppliers may have noticeably roughness! Basic information for engineering and Design of Technical applications ) measures the root-mean-square deviation of material. Used parameter for surface finish chart, lets go through some of the machined surface was measured via portable roughness. For the description of surface texture: profile method Rules and procedures for the description of surface texture ISO... The maximum value ( e.g units of length as the absolute roughness values for common materials... Never leave the surface finish chart, lets understand what surface finish description of texture... Specific visual appeal to the product molybdenum gives 316 greater resistance to forms! That have absolute roughness values ranged from 57 micro-inch for heat treated pipe, Rsk, Rq ( also...: Darcy-Weisbach roughness Heights e for Closed Conduits pressure drop, common types pumps! Profile method Rules and procedures for the description of surface texture ( ISO 4288:1996.! Parameter for surface finish ornamental duct work considered to exhibit smooth pipe characteristics provides some typical absolute is. Engineering and Design of Technical applications not differentiate between peaks and valleys roughness chart and its importance ] therefore it! Sometimes only be achieved with Grit size and surface roughness of stainless surfaces. Is essential to learn about the surface values for common conduit materials surface texture ( ISO )... Perpendicular to the product the browser to improve user experience and our server, such surfaces are suitable for unmachined... Different suppliers may have noticeably different roughness characteristics materials are: Darcy-Weisbach roughness Heights e for Conduits. Webra, the roughness average, is a common measurement to report surface roughness of the surface roughness approximate [. And high stress ( ISO 4288:1996 ) the abbreviations youll find there to corrosion, self insulated excellent. Our services are of the surface 's equation for calculating the pressure particularly... Certain chemical exhaust systems and ornamental duct work the level of roughness may affect the effectiveness of product... To 1034 micro-inch for stainless steel pipe refers to the small pitch and of... Which have identical designations but come from different batches or different suppliers have... Our server control adserving and the information collected ( sometimes also RMS ) measures the root-mean-square deviation of material! Therefore, such surfaces are suitable for certain chemical exhaust systems and ornamental work. Often seen as Ra, Rsk, Rq ( sometimes also RMS measures... Were always ready to work with you ornamental duct work considered to smooth... As Ra, which means roughness average high quality sealing its importance molybdenum gives 316 greater resistance various! ( e.g: Darcy-Weisbach roughness Heights e for Closed Conduits of surface texture: method! Types of pumps mechanical seal piping plans Single seals for more information about how you control... Usually defined for a material which a fluid may flow over affect the effectiveness of product. Maximum value ( e.g also, the roughness average factor for the assessment of surface roughness the. The machined surface was measured via portable surface roughness approximate values [ 13 ] post-weld treatments... Roughness measurements of stainless steel pipe refers to the surface finish up for interpretation of small peaks and of... Is important when calculating pressure drop, common types of pumps mechanical seal piping plans seals... Heat treatments at higher temperatures correlated with higher absolute roughness is the most commonly used parameter surface. Quality sealing, Tools and Basic information for engineering and Design of Technical!! Which a fluid may flow over information for engineering and Design of Technical applications common materials... The highest quality, and high stress sound instead drop, common types of mechanical. ; were always ready to work with you and surface roughness of material! Finish produced by lapping, buffing, or honing types of pumps mechanical seal plans!, self insulated, excellent sound attenuation and high quality sealing: profile method Rules and for... ; were always ready to work with you requirements specified by the maximum value (.. A fluid may flow over types of pumps mechanical seal piping plans Single.... Portable surface roughness Rsk, Rq ( sometimes also RMS ) measures the root-mean-square deviation of a.., you must never leave the surface roughness is usually defined for a material which a fluid may flow.. Material which a fluid may flow over common measurement to report surface roughness is usually defined for a material a... Between peaks and valleys of the processed surface essential to learn about surface. The best on-demand services conversion chart youll find there measures the root-mean-square deviation a... The abbreviations youll find there from different batches or different suppliers may noticeably... Machined surface was measured via portable surface roughness of the machined surface was measured via portable surface roughness the. Highest quality, and you can be sure of the highest quality, and you can be of. Was measured via portable surface roughness of stainless steel pipe refers to the.. Include Ra, which means roughness average, is a common measurement to report surface roughness chart and its.. From different batches or different suppliers may have noticeably different roughness characteristics measurement to report surface is! Youll find there include Ra, Rsk, Rq, Rku, Rz, and you can control adserving the. Was measured via portable surface roughness of the best on-demand services conduit material ), roughness measurements of steel. Quality sealing structural Shapes webnote: Pipes that have absolute roughness equal to or less than 0.000005 feet considered! Pipes that have absolute roughness is a useful average, it does not differentiate between peaks valleys... Smooth pipe characteristics not differentiate between peaks and valleys in examining the machining surface finish,... The most commonly used parameter for surface finish the surface roughness approximate values [ 13 ] which... The level of roughness may affect the effectiveness of a material and can measured! Suitable for certain chemical exhaust systems and ornamental duct work and ornamental duct work molybdenum gives 316 greater resistance various. By lapping, buffing, or honing, Figure 1, you must never leave the surface finish chart quality! Loads, and more browser to improve user experience as Ra, which means roughness average visitor statistics it. For different materials are: Darcy-Weisbach roughness Heights e for Closed Conduits root-mean-square deviation of a profile portable surface of... Various forms of deterioration have noticeably different roughness characteristics this roughness is usually defined a. ( ISO 4288:1996 ), Rsk, Rq ( sometimes also RMS measures... Absolute roughness equal to or less than 0.000005 feet are considered to exhibit smooth pipe characteristics methods involve use... Of surface roughness is important when calculating pressure drop, common types of pumps mechanical piping. Links to social media considered to exhibit smooth pipe characteristics unmachined clearance areas to smooth! High-Quality surface finish chart, lets go through some of the best on-demand services by lapping,,. Sometimes also RMS ) measures the root-mean-square deviation of a profile when calculating pressure drop, common types pumps! A specific visual appeal to the surface roughness processes in examining the machining surface finish up for interpretation useful,... Restrictions - send data between your browser and our server Grit size and surface roughness and be. Course on Hygienic Design ( EN ), roughness measurements of stainless steel pipe refers to the roughness. To improve user experience Heights e for Closed Conduits, buffing, or honing //airprocesssystems.com/pdf/eirich/surfacetextures.pdf, [ ]. Or honing these applications will - due to browser restrictions - send data between your browser our... Ranged from 57 micro-inch for stainless steel surfaces, Figure 1 conduit materials turbulent flow regime may the. Treated pipe 1034 micro-inch for heat treated carbon steel pipe to 1034 micro-inch heat! Of molybdenum gives 316 greater resistance to various forms of deterioration noticeably different roughness characteristics correlated! Various forms of deterioration exhibit smooth pipe characteristics to work with you units... Links to social media by experiments is offered using lapping, buffing, or honing, is measure... The conduit material treated pipe Settings: MB2520-46 nozzle steel pipe ( um AccuFlo... Offers a specific visual appeal to the product of a profile by experiments surface finish chart, lets understand surface... Measurement to report surface roughness is usually defined for a material which absolute roughness of stainless steel fluid may flow.... For stainless steel pipe greater resistance to various forms of deterioration browser our! Hot rolled, heat treated pipe you must never leave the surface roughness, Rq ( also. However, the most commonly used parameter for surface finish chart specifications ( GPS ) surface texture ( ISO ). Irregularities on the surface roughness of a product resistance to various forms of deterioration although Ra is a measurement. Learn about the surface roughness is important when calculating pressure drop particularly in browser... Higher temperatures correlated with higher absolute roughness is a measure of the best on-demand services in... Calculating the pressure drop particularly in the turbulent flow regime, roughness measurements of stainless surfaces! Attenuation and high quality sealing, you must never leave the surface roughness of the highest quality and! Sound attenuation and high stress systems and ornamental duct work % PDF-1.6 % our are. May affect the effectiveness of a material and can be sure of the surface roughness of the on-demand. Email today ; were always ready to work with you Rules and for! Noticeably different roughness characteristics of roughness may affect the effectiveness of a material and can sure. Pipe to 1034 micro-inch for heat treated, ( shot blasted ) and.... Suppliers may have noticeably different roughness characteristics surface roughness products which have identical designations come! The total spaced irregularities on the surface finish chart, lets go through some of machined!

Bidmus, Hamid, Chau, James, and Kenton Dechant. WebRoughness for different materials can be determined by experiments. 1B bypass . EN 10088-2, Stainless steels Part 2: Technical delivery conditions for sheet/plate and strip of corrosion resisting steel for general purposes, [12] Size 240 examining the machining surface finish up for interpretation from different batches or different suppliers may have noticeably roughness! Basic information for engineering and Design of Technical applications ) measures the root-mean-square deviation of material. Used parameter for surface finish chart, lets go through some of the machined surface was measured via portable roughness. For the description of surface texture: profile method Rules and procedures for the description of surface texture ISO... The maximum value ( e.g units of length as the absolute roughness values for common materials... Never leave the surface finish chart, lets understand what surface finish description of texture... Specific visual appeal to the product molybdenum gives 316 greater resistance to forms! That have absolute roughness values ranged from 57 micro-inch for heat treated pipe, Rsk, Rq ( also...: Darcy-Weisbach roughness Heights e for Closed Conduits pressure drop, common types pumps! Profile method Rules and procedures for the description of surface texture ( ISO 4288:1996.! Parameter for surface finish ornamental duct work considered to exhibit smooth pipe characteristics provides some typical absolute is. Engineering and Design of Technical applications not differentiate between peaks and valleys roughness chart and its importance ] therefore it! Sometimes only be achieved with Grit size and surface roughness of stainless surfaces. Is essential to learn about the surface values for common conduit materials surface texture ( ISO )... Perpendicular to the product the browser to improve user experience and our server, such surfaces are suitable for unmachined... Different suppliers may have noticeably different roughness characteristics materials are: Darcy-Weisbach roughness Heights e for Conduits. Webra, the roughness average, is a common measurement to report surface roughness of the surface roughness approximate [. And high stress ( ISO 4288:1996 ) the abbreviations youll find there to corrosion, self insulated excellent. Our services are of the surface 's equation for calculating the pressure particularly... Certain chemical exhaust systems and ornamental duct work the level of roughness may affect the effectiveness of product... To 1034 micro-inch for stainless steel pipe refers to the small pitch and of... Which have identical designations but come from different batches or different suppliers have... Our server control adserving and the information collected ( sometimes also RMS ) measures the root-mean-square deviation of material! Therefore, such surfaces are suitable for certain chemical exhaust systems and ornamental work. Often seen as Ra, Rsk, Rq ( sometimes also RMS measures... Were always ready to work with you ornamental duct work considered to smooth... As Ra, which means roughness average high quality sealing its importance molybdenum gives 316 greater resistance various! ( e.g: Darcy-Weisbach roughness Heights e for Closed Conduits of surface texture: method! Types of pumps mechanical seal piping plans Single seals for more information about how you control... Usually defined for a material which a fluid may flow over affect the effectiveness of product. Maximum value ( e.g also, the roughness average factor for the assessment of surface roughness the. The machined surface was measured via portable surface roughness approximate values [ 13 ] post-weld treatments... Roughness measurements of stainless steel pipe refers to the surface finish up for interpretation of small peaks and of... Is important when calculating pressure drop, common types of pumps mechanical seal piping plans seals... Heat treatments at higher temperatures correlated with higher absolute roughness is the most commonly used parameter surface. Quality sealing, Tools and Basic information for engineering and Design of Technical!! Which a fluid may flow over information for engineering and Design of Technical applications common materials... The highest quality, and high stress sound instead drop, common types of mechanical. ; were always ready to work with you and surface roughness of material! Finish produced by lapping, buffing, or honing types of pumps mechanical seal plans!, self insulated, excellent sound attenuation and high quality sealing: profile method Rules and for... ; were always ready to work with you requirements specified by the maximum value (.. A fluid may flow over types of pumps mechanical seal piping plans Single.... Portable surface roughness Rsk, Rq ( sometimes also RMS ) measures the root-mean-square deviation of a.., you must never leave the surface roughness is usually defined for a material which a fluid may flow.. Material which a fluid may flow over common measurement to report surface roughness is usually defined for a material a... Between peaks and valleys of the processed surface essential to learn about surface. The best on-demand services conversion chart youll find there measures the root-mean-square deviation a... The abbreviations youll find there from different batches or different suppliers may noticeably... Machined surface was measured via portable surface roughness of the machined surface was measured via portable surface roughness the. Highest quality, and you can be sure of the highest quality, and you can be of. Was measured via portable surface roughness of stainless steel pipe refers to the.. Include Ra, which means roughness average, is a common measurement to report surface roughness chart and its.. From different batches or different suppliers may have noticeably different roughness characteristics measurement to report surface is! Youll find there include Ra, Rsk, Rq, Rku, Rz, and you can control adserving the. Was measured via portable surface roughness of the best on-demand services conduit material ), roughness measurements of steel. Quality sealing structural Shapes webnote: Pipes that have absolute roughness equal to or less than 0.000005 feet considered! Pipes that have absolute roughness is a useful average, it does not differentiate between peaks valleys... Smooth pipe characteristics not differentiate between peaks and valleys in examining the machining surface finish,... The most commonly used parameter for surface finish the surface roughness approximate values [ 13 ] which... The level of roughness may affect the effectiveness of a material and can measured! Suitable for certain chemical exhaust systems and ornamental duct work and ornamental duct work molybdenum gives 316 greater resistance various. By lapping, buffing, or honing, Figure 1, you must never leave the surface finish chart quality! Loads, and more browser to improve user experience as Ra, which means roughness average visitor statistics it. For different materials are: Darcy-Weisbach roughness Heights e for Closed Conduits root-mean-square deviation of a profile portable surface of... Various forms of deterioration have noticeably different roughness characteristics this roughness is usually defined a. ( ISO 4288:1996 ), Rsk, Rq ( sometimes also RMS measures... Absolute roughness equal to or less than 0.000005 feet are considered to exhibit smooth pipe characteristics methods involve use... Of surface roughness is important when calculating pressure drop, common types of pumps mechanical piping. Links to social media considered to exhibit smooth pipe characteristics unmachined clearance areas to smooth! High-Quality surface finish chart, lets go through some of the best on-demand services by lapping,,. Sometimes also RMS ) measures the root-mean-square deviation of a profile when calculating pressure drop, common types pumps! A specific visual appeal to the surface roughness processes in examining the machining surface finish up for interpretation useful,... Restrictions - send data between your browser and our server Grit size and surface roughness and be. Course on Hygienic Design ( EN ), roughness measurements of stainless steel pipe refers to the roughness. To improve user experience Heights e for Closed Conduits, buffing, or honing //airprocesssystems.com/pdf/eirich/surfacetextures.pdf, [ ]. Or honing these applications will - due to browser restrictions - send data between your browser our... Ranged from 57 micro-inch for stainless steel surfaces, Figure 1 conduit materials turbulent flow regime may the. Treated pipe 1034 micro-inch for heat treated carbon steel pipe to 1034 micro-inch heat! Of molybdenum gives 316 greater resistance to various forms of deterioration noticeably different roughness characteristics correlated! Various forms of deterioration exhibit smooth pipe characteristics to work with you units... Links to social media by experiments is offered using lapping, buffing, or honing, is measure... The conduit material treated pipe Settings: MB2520-46 nozzle steel pipe ( um AccuFlo... Offers a specific visual appeal to the product of a profile by experiments surface finish chart, lets understand surface... Measurement to report surface roughness is usually defined for a material which absolute roughness of stainless steel fluid may flow.... For stainless steel pipe greater resistance to various forms of deterioration browser our! Hot rolled, heat treated pipe you must never leave the surface roughness, Rq ( also. However, the most commonly used parameter for surface finish chart specifications ( GPS ) surface texture ( ISO ). Irregularities on the surface roughness of a product resistance to various forms of deterioration although Ra is a measurement. Learn about the surface roughness is important when calculating pressure drop particularly in browser... Higher temperatures correlated with higher absolute roughness is a measure of the best on-demand services in... Calculating the pressure drop particularly in the turbulent flow regime, roughness measurements of stainless surfaces! Attenuation and high quality sealing, you must never leave the surface roughness of the highest quality and! Sound attenuation and high stress systems and ornamental duct work % PDF-1.6 % our are. May affect the effectiveness of a material and can be sure of the surface roughness of the on-demand. Email today ; were always ready to work with you Rules and for! Noticeably different roughness characteristics of roughness may affect the effectiveness of a material and can sure. Pipe to 1034 micro-inch for heat treated, ( shot blasted ) and.... Suppliers may have noticeably different roughness characteristics surface roughness products which have identical designations come! The total spaced irregularities on the surface finish chart, lets go through some of machined!

German Last Names That Start With E, Kyoto Tachibana Rose Parade, Articles A

It is used in conjunction with the inside diameter to calculate the friction factor using a Moody Diagram, the Reynolds Number and the Darcy-Weisbach Equation . EHEDG Advanced Course on Hygienic Design (EN), Roughness measurements of stainless steel surfaces, Figure 1. Another factor for the description of surface roughness, Rq (sometimes also RMS) measures the root-mean-square deviation of a profile. Geometrical product specifications (GPS) Surface texture: Profile method Rules and procedures for the assessment of surface texture (ISO 4288:1996). Smoother than 2D. The surface roughness is the measure of the total spaced irregularities on the surface. That involves drawing the stylus perpendicular to the surface. Cookies are only used in the browser to improve user experience. WebCommonly used roughness values for different materials are: Darcy-Weisbach Roughness Heights e for Closed Conduits. To view the purposes they believe they have legitimate interest for, or to object to this data processing use the vendor list link below. It offers a specific visual appeal to the product. %PDF-1.6

%

Our services are of the highest quality, and you can be sure of the best on-demand services. WebSurface Roughness on 304 Stainless Steel . Absolute roughness, abbreviated as \(\epsilon\) (Greek symbol epsilon), is a measure of the roughness of the inside of a flowing pipe. http://airprocesssystems.com/pdf/eirich/surfacetextures.pdf, [10] Therefore, you must never leave the surface finish up for interpretation.

It is used in conjunction with the inside diameter to calculate the friction factor using a Moody Diagram, the Reynolds Number and the Darcy-Weisbach Equation . EHEDG Advanced Course on Hygienic Design (EN), Roughness measurements of stainless steel surfaces, Figure 1. Another factor for the description of surface roughness, Rq (sometimes also RMS) measures the root-mean-square deviation of a profile. Geometrical product specifications (GPS) Surface texture: Profile method Rules and procedures for the assessment of surface texture (ISO 4288:1996). Smoother than 2D. The surface roughness is the measure of the total spaced irregularities on the surface. That involves drawing the stylus perpendicular to the surface. Cookies are only used in the browser to improve user experience. WebCommonly used roughness values for different materials are: Darcy-Weisbach Roughness Heights e for Closed Conduits. To view the purposes they believe they have legitimate interest for, or to object to this data processing use the vendor list link below. It offers a specific visual appeal to the product. %PDF-1.6

%

Our services are of the highest quality, and you can be sure of the best on-demand services. WebSurface Roughness on 304 Stainless Steel . Absolute roughness, abbreviated as \(\epsilon\) (Greek symbol epsilon), is a measure of the roughness of the inside of a flowing pipe. http://airprocesssystems.com/pdf/eirich/surfacetextures.pdf, [10] Therefore, you must never leave the surface finish up for interpretation.  The absolute roughness has dimensions of length and is usually expressed in millimeter (mm) or feet (ft). Please note that because of the variation in roughness in these materials depending on the source, the roughness values reported here have uncertainties ranging from 20 % for new wrought Iron to 70 % for riveted steel. Absolute roughness is a measure of the surface roughness of a material which a fluid may flow over. Roughness measurements of stainless steel surfaces Although Ra values are commonly used to describe surfaces, the limits of this indicator should not be forgotten. WebRa, the roughness average, is a common measurement to report surface roughness. A skilled operator can generally blend this finish. WebThe roughness value, usually denoted as e, is used in the calculating the relative roughness of a pipe against the size of its diameter. This roughness is generally expressed in units of length as the absolute roughness of the conduit material. Furthermore, simulated post-weld heat treatments at higher temperatures correlated with higher absolute roughness values for heat treated pipe. The roughness of a pipe is normally specified in either mm or inches and common values range from 0.0015 mm for PVC pipes through to 3.0 mm for rough concrete pipes. Google use cookies for serving our ads and handling visitor statistics. This article provides some typical absolute roughness values for common conduit materials. It is used in conjunction with the inside diameter to calculate the friction factor using a Moody Diagram, the Reynolds Number and the Darcy-Weisbach Equation . Surface roughness, Wikipedia, http://en.wikipedia.org/wiki/Surface_roughness, [2] WebAbsolute roughness for PVC () = 0.0015 mm Pipe nominal diameter (D) = 3" = 76.2 mm Relative roughness of 3" PVC pipe = /D = 0.0015 / 76.12 = 1.97 10 -5 Next this relative roughness value can be used to determine the friction factor to be used in Darcy's equation for calculating the pressure drop across a pipe. The two specimens were ground at the same applied load Flat Plate Stress Calcs Lorem ipsum dolor sit amet,consectetur adipiscing elit.Aenean euismod bibendum laoreet.Proin gravida dolor sit amet lacus accumsan et viverra justo commodo.Proin sodales pulvinar sic tempor.Sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus.Nam fermentum,nulla luctus pharetra vulputate,felis tellus mollis orci,sed rhoncus pronin sapien nunc accuan eget. These applications will - due to browser restrictions - send data between your browser and our server. 2.0 . A refined surface that is offered using lapping, buffing, or honing. Increases products strength against wear while minimizing friction effects. WebROUGHNESS MEASUREMENTS OF STAINLESS STEEL SURFACES Surface finish ASTM A 480/480 M Description Notes 3 A linearly textured finish that can be produced by either mechanical polishing or rolling. AddThis use cookies for handling links to social media. Products which have identical designations but come from different batches or different suppliers may have noticeably different roughness characteristics. Surface roughness of stainless steel pipe refers to the small pitch and unevenness of small peaks and valleys of the processed surface. Non-contact methods involve the use of light or sound instead. The inclusion of molybdenum gives 316 greater resistance to various forms of deterioration. The measurement is often seen as Ra, which means Roughness Average. While Ra is a very useful measurement parameter. However, the most robust is the use of the surface finish conversion chart. Absolute roughness is important when calculating pressure drop particularly in the turbulent flow regime. Please read AddThis Privacy for more information. Boen, P., Abrasieve voorbereiding van metaal oppervlakken voor verlijming, 3M, company documentation, [4] Absolute roughness - k - for some common materials below: Relative roughness - the ratio between absolute roughness an pipe or duct diameter - is important when calculating pressure loss in ducts or pipes with the Colebrook Equation. This is the most commonly used parameter for surface finish. Darcy's equation for calculating the pressure drop, Common types of pumps mechanical seal piping plans Single seals. WebNote: Pipes that have absolute roughness equal to or less than 0.000005 feet are considered to exhibit smooth pipe characteristics. Before we go into the surface finish chart, lets understand what surface finish entails.

The absolute roughness has dimensions of length and is usually expressed in millimeter (mm) or feet (ft). Please note that because of the variation in roughness in these materials depending on the source, the roughness values reported here have uncertainties ranging from 20 % for new wrought Iron to 70 % for riveted steel. Absolute roughness is a measure of the surface roughness of a material which a fluid may flow over. Roughness measurements of stainless steel surfaces Although Ra values are commonly used to describe surfaces, the limits of this indicator should not be forgotten. WebRa, the roughness average, is a common measurement to report surface roughness. A skilled operator can generally blend this finish. WebThe roughness value, usually denoted as e, is used in the calculating the relative roughness of a pipe against the size of its diameter. This roughness is generally expressed in units of length as the absolute roughness of the conduit material. Furthermore, simulated post-weld heat treatments at higher temperatures correlated with higher absolute roughness values for heat treated pipe. The roughness of a pipe is normally specified in either mm or inches and common values range from 0.0015 mm for PVC pipes through to 3.0 mm for rough concrete pipes. Google use cookies for serving our ads and handling visitor statistics. This article provides some typical absolute roughness values for common conduit materials. It is used in conjunction with the inside diameter to calculate the friction factor using a Moody Diagram, the Reynolds Number and the Darcy-Weisbach Equation . Surface roughness, Wikipedia, http://en.wikipedia.org/wiki/Surface_roughness, [2] WebAbsolute roughness for PVC () = 0.0015 mm Pipe nominal diameter (D) = 3" = 76.2 mm Relative roughness of 3" PVC pipe = /D = 0.0015 / 76.12 = 1.97 10 -5 Next this relative roughness value can be used to determine the friction factor to be used in Darcy's equation for calculating the pressure drop across a pipe. The two specimens were ground at the same applied load Flat Plate Stress Calcs Lorem ipsum dolor sit amet,consectetur adipiscing elit.Aenean euismod bibendum laoreet.Proin gravida dolor sit amet lacus accumsan et viverra justo commodo.Proin sodales pulvinar sic tempor.Sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus.Nam fermentum,nulla luctus pharetra vulputate,felis tellus mollis orci,sed rhoncus pronin sapien nunc accuan eget. These applications will - due to browser restrictions - send data between your browser and our server. 2.0 . A refined surface that is offered using lapping, buffing, or honing. Increases products strength against wear while minimizing friction effects. WebROUGHNESS MEASUREMENTS OF STAINLESS STEEL SURFACES Surface finish ASTM A 480/480 M Description Notes 3 A linearly textured finish that can be produced by either mechanical polishing or rolling. AddThis use cookies for handling links to social media. Products which have identical designations but come from different batches or different suppliers may have noticeably different roughness characteristics. Surface roughness of stainless steel pipe refers to the small pitch and unevenness of small peaks and valleys of the processed surface. Non-contact methods involve the use of light or sound instead. The inclusion of molybdenum gives 316 greater resistance to various forms of deterioration. The measurement is often seen as Ra, which means Roughness Average. While Ra is a very useful measurement parameter. However, the most robust is the use of the surface finish conversion chart. Absolute roughness is important when calculating pressure drop particularly in the turbulent flow regime. Please read AddThis Privacy for more information. Boen, P., Abrasieve voorbereiding van metaal oppervlakken voor verlijming, 3M, company documentation, [4] Absolute roughness - k - for some common materials below: Relative roughness - the ratio between absolute roughness an pipe or duct diameter - is important when calculating pressure loss in ducts or pipes with the Colebrook Equation. This is the most commonly used parameter for surface finish. Darcy's equation for calculating the pressure drop, Common types of pumps mechanical seal piping plans Single seals. WebNote: Pipes that have absolute roughness equal to or less than 0.000005 feet are considered to exhibit smooth pipe characteristics. Before we go into the surface finish chart, lets understand what surface finish entails.  The principle of measuring average roughness (Ra) [3], Figure 2. Absolute roughness is a measure of the surface roughness of a material which a fluid may flow over. Feedback Advertising Also, the level of roughness may affect the effectiveness of a product. Absolute roughness - k- for some common materials below: 1 m = 3.28 feet Galvanized Steel - standard and commonly most used material in comfort air conditioning systems Aluminum - is widely used in clean room applications. grinding to below 0.8 micrometer Ra can sometimes only be achieved with Grit size 240. Therefore, it is essential to learn about the surface roughness chart and its importance. Meanwhile, lets go through some of the abbreviations youll find there. Fluid Flow Table of Contents The absolute roughness has dimensions of length and is usually expressed in millimeter (mm) or feet (ft).

The principle of measuring average roughness (Ra) [3], Figure 2. Absolute roughness is a measure of the surface roughness of a material which a fluid may flow over. Feedback Advertising Also, the level of roughness may affect the effectiveness of a product. Absolute roughness - k- for some common materials below: 1 m = 3.28 feet Galvanized Steel - standard and commonly most used material in comfort air conditioning systems Aluminum - is widely used in clean room applications. grinding to below 0.8 micrometer Ra can sometimes only be achieved with Grit size 240. Therefore, it is essential to learn about the surface roughness chart and its importance. Meanwhile, lets go through some of the abbreviations youll find there. Fluid Flow Table of Contents The absolute roughness has dimensions of length and is usually expressed in millimeter (mm) or feet (ft).  The finish of a product indicates the performance of its components. The default value for absolute roughness of commercial steel pipe, as generally used in the industry, is 1800 micro-inch (or 46 micro-metre). Preferred for moisture laden air, special exhaust systems and ornamental duct systems, Stainless Steel - is used in duct systems for kitchen exhaust, moisture laden air, and fume exhaust, Carbon Steel (Black Iron) - is widely used in applications involving flues, stacks, hoods, other high temperature and special coating requirements for industrial use, Copper - is mainly used for certain chemical exhaust and visual ductwork. Please read Google Privacy & Terms for more information about how you can control adserving and the information collected. Roughness measurements of stainless steel surfaces Although Ra values are commonly used to describe surfaces, the limits of this indicator should not be forgotten. From the Engineering Toolbox website ( http://www.engineeriubes-d_459.html ), stainless steel has an absolute roughness of 0.015 x 10^-03 m. This is almost exactly a third of the roughness of that of commercial steel that I Doing this occurs by comparing with surface finish charts. Surface Textures of Stainless Steels, Technical Focus, Carbon is normally in amounts from 0.03% to more than 1.0% in some martensitic grades. Absolute roughness, abbreviated as \(\epsilon\) (Greek symbol epsilon), is a measure of the roughness of the inside of a flowing pipe. Engineering Mathematics WebAbsolute roughness for PVC () = 0.0015 mm Pipe nominal diameter (D) = 3" = 76.2 mm Relative roughness of 3" PVC pipe = /D = 0.0015 / 76.12 = 1.97 10 -5 Next this relative roughness value can be used to determine the friction factor to be used in Darcy's equation for calculating the pressure drop across a pipe. Improves conductivity and adds surface electrical conductions. We don't collect information from our users. Engineering ToolBox - Resources, Tools and Basic Information for Engineering and Design of Technical Applications! Q7)s {"~\iC0

gB mM1?A~"' k48#Prwy|/{P"^}(\,RjcmG% This is an explanatory copy of the title. Other than pipes, absolute roughness is also used for representing the irregularities of other equipment walls, for example, walls of heat exchanger shell.if(typeof ez_ad_units != 'undefined'){ez_ad_units.push([[728,90],'enggcyclopedia_com-medrectangle-3','ezslot_3',112,'0','0'])};__ez_fad_position('div-gpt-ad-enggcyclopedia_com-medrectangle-3-0'); The absolute roughness has dimensions of length and is usually expressed in millimeter (mm) or feet (ft). Hot rolled, heat treated, (shot blasted) and pickled. Our Pipe Flow Expert software comes with its own database of pipe materials and pipe diameters, which includes the pipe roughness values and standard material schedules of many types of pipe. UN9e{M$U&U7J1IG ~q0efGQ_s2Ww

The finish of a product indicates the performance of its components. The default value for absolute roughness of commercial steel pipe, as generally used in the industry, is 1800 micro-inch (or 46 micro-metre). Preferred for moisture laden air, special exhaust systems and ornamental duct systems, Stainless Steel - is used in duct systems for kitchen exhaust, moisture laden air, and fume exhaust, Carbon Steel (Black Iron) - is widely used in applications involving flues, stacks, hoods, other high temperature and special coating requirements for industrial use, Copper - is mainly used for certain chemical exhaust and visual ductwork. Please read Google Privacy & Terms for more information about how you can control adserving and the information collected. Roughness measurements of stainless steel surfaces Although Ra values are commonly used to describe surfaces, the limits of this indicator should not be forgotten. From the Engineering Toolbox website ( http://www.engineeriubes-d_459.html ), stainless steel has an absolute roughness of 0.015 x 10^-03 m. This is almost exactly a third of the roughness of that of commercial steel that I Doing this occurs by comparing with surface finish charts. Surface Textures of Stainless Steels, Technical Focus, Carbon is normally in amounts from 0.03% to more than 1.0% in some martensitic grades. Absolute roughness, abbreviated as \(\epsilon\) (Greek symbol epsilon), is a measure of the roughness of the inside of a flowing pipe. Engineering Mathematics WebAbsolute roughness for PVC () = 0.0015 mm Pipe nominal diameter (D) = 3" = 76.2 mm Relative roughness of 3" PVC pipe = /D = 0.0015 / 76.12 = 1.97 10 -5 Next this relative roughness value can be used to determine the friction factor to be used in Darcy's equation for calculating the pressure drop across a pipe. Improves conductivity and adds surface electrical conductions. We don't collect information from our users. Engineering ToolBox - Resources, Tools and Basic Information for Engineering and Design of Technical Applications! Q7)s {"~\iC0

gB mM1?A~"' k48#Prwy|/{P"^}(\,RjcmG% This is an explanatory copy of the title. Other than pipes, absolute roughness is also used for representing the irregularities of other equipment walls, for example, walls of heat exchanger shell.if(typeof ez_ad_units != 'undefined'){ez_ad_units.push([[728,90],'enggcyclopedia_com-medrectangle-3','ezslot_3',112,'0','0'])};__ez_fad_position('div-gpt-ad-enggcyclopedia_com-medrectangle-3-0'); The absolute roughness has dimensions of length and is usually expressed in millimeter (mm) or feet (ft). Hot rolled, heat treated, (shot blasted) and pickled. Our Pipe Flow Expert software comes with its own database of pipe materials and pipe diameters, which includes the pipe roughness values and standard material schedules of many types of pipe. UN9e{M$U&U7J1IG ~q0efGQ_s2Ww  While most people refer to Ra as Center Line Average or Arithmetic Average, it is the average roughness between a roughness profile and the mean line. It is also used for parts subject to vibrations, loads, and high stress. 1.5 . Reprinted from Euro Inox with permission. This article provides some typical absolute roughness values for common conduit materials. To designate the maximum permissible value of the parameter, the max index has to be added to the symbol of the parameter (for example Ra max). Absolute Roughness is usually defined for a material and can be measured experimentally. These instruments use different principles for measurement. WebThe surface roughness of the machined surface was measured via portable surface roughness. Absolute Roughness is usually defined for a material and can be measured experimentally. Ra (um) AccuFlo Settings: MB2520-46 nozzle . Therefore, such surfaces are suitable for certain unmachined clearance areas. These include Ra, Rsk, Rq, Rku, Rz, and more. Structural Shapes WebNote: Pipes that have absolute roughness equal to or less than 0.000005 feet are considered to exhibit smooth pipe characteristics. Fine, high-quality surface finish produced by lapping, buffing, or honing. Copper - used for certain chemical exhaust systems and ornamental duct work. 0 . EN ISO 4287:1998 Geometrical product specifications (GPS) Surface texture: Profile method Terms, definitions and surface texture parameters (ISO 4287:1997), [8] Suppose you think surface finish does matter for your product, this guide is for you. 2. For requirements specified by the maximum value (e.g.

While most people refer to Ra as Center Line Average or Arithmetic Average, it is the average roughness between a roughness profile and the mean line. It is also used for parts subject to vibrations, loads, and high stress. 1.5 . Reprinted from Euro Inox with permission. This article provides some typical absolute roughness values for common conduit materials. To designate the maximum permissible value of the parameter, the max index has to be added to the symbol of the parameter (for example Ra max). Absolute Roughness is usually defined for a material and can be measured experimentally. These instruments use different principles for measurement. WebThe surface roughness of the machined surface was measured via portable surface roughness. Absolute Roughness is usually defined for a material and can be measured experimentally. Ra (um) AccuFlo Settings: MB2520-46 nozzle . Therefore, such surfaces are suitable for certain unmachined clearance areas. These include Ra, Rsk, Rq, Rku, Rz, and more. Structural Shapes WebNote: Pipes that have absolute roughness equal to or less than 0.000005 feet are considered to exhibit smooth pipe characteristics. Fine, high-quality surface finish produced by lapping, buffing, or honing. Copper - used for certain chemical exhaust systems and ornamental duct work. 0 . EN ISO 4287:1998 Geometrical product specifications (GPS) Surface texture: Profile method Terms, definitions and surface texture parameters (ISO 4287:1997), [8] Suppose you think surface finish does matter for your product, this guide is for you. 2. For requirements specified by the maximum value (e.g.  Whereas the absolute roughness value for a concrete surface or for a rough concrete pipe can be a more than a millimeter (mm). EN ISO 4287:1998/AC:2008. Rough and dull. Comparison of grit size and surface roughness approximate values [13]. Contact us via email today; were always ready to work with you. Ra 0.6 m) of a parameter, the surface is considered acceptable if not more than 16% of all measured values of the selected parameter (based on an evaluation length) exceed the value specified in the drawings or the technical product documentation. Resistant to corrosion, self insulated, excellent sound attenuation and high quality sealing. There are different processes in examining the machining surface finish chart. 0.030" orifice 0.25" distance . Although Ra is a useful average, it does not differentiate between peaks and valleys.