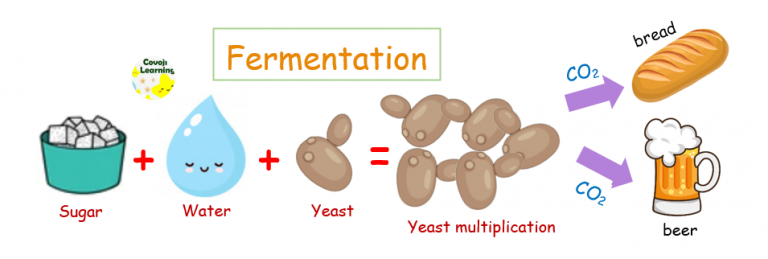

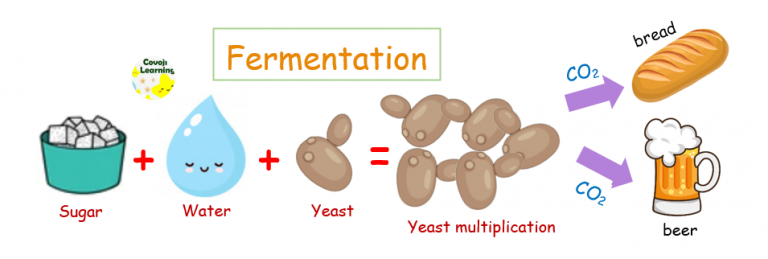

Glucose is used first, then fructose and sucrose. A typical beer brew takes four weeks to complete. Fermentation is usually divided into three stages: primary, secondary, and conditioning (or lagering). The malting process results in partial germination of the barley grains.  Military / 1st Responder Discount, Privacy Policy During fermentation wort sugars are consumed, with new yeast cells forming with ethanol and CO2 produced as well, along with flavor compounds. Brewers use a germination room where the grains are spread on the floor for about five days to promote germination. The soft texture makes it easier for beta-amylases to separate maltose from starch. Youll also see brown spots in the krausen, from oxidized hop resins. After maltose enters the cell through a special uptake mechanism, it is hydrolyzed into glucose units by maltase enzymes. During fermentation, yeast converts the sugary wort into actual beer by producing alcohol, a wide range of flavours and carbon dioxide (which is used later in the brewing process to carbonate the beer. Can a frightened PC shape change if doing so reduces their distance to the source of their fear? As the beers enter the stationary phase, yeast growth slows down. To begin the fermentation process, the cooled wort is transferred into a fermentation vessel to which the yeast has already been added. Such mixed fermentation involving different yeast strains adds a complexity to the beer flavor. You will get some action with in the first 24 hours of pitching your yeast but not a lot. Facebook Group During wort making fermentable sugars from malt are combined with the flavor and antioxidant Different strains of beer yeast will do different things when fermented in beer. The first evidence that shows fermentation is underway is the presence of bubbles in the airlock. ), Exponential Growth Phase: One to Four Days. Learn how and where you too can join the hunt for novel yeast strains. Most common yeasts are distillers and bakers. Making statements based on opinion; back them up with references or personal experience. This website uses cookies to improve your experience while you navigate through the website. For example, a malt that is roasted lightly gives a pale beer while heavily-roasted malt produces dark-colored beer. The kraeusen falls, and yeast begin to settle out, or flocculate. I know my lager will ferment but the wait, gets me every time. Pipewrench Gigantic Brewing. Once bottled, ales (bitter, IPA, stout, etc.) No-rinse sanitisers such as Star san take just a few minutes to sanitise everything. }); Professional breweries cool the contents of the fermenter gradually to 35 to 40 F, which forces most of the yeast to flocculate. If the beer being made is an ale, the wort will be maintained at a constant temperature of Primary During the first stage, the yeast performs aerobic respiration, and undergoes a series of changes to adapt to its new environment, hence the name Adaptive Phase . Post-apoc YA novel with a focus on pre-war totems. You never master brewing; Ive been making beer for over 25 years now; Im still learning all the time. The time of soaking is about 40 hours. You also have the option to opt-out of these cookies. The frothing results from the evolution of carbon dioxide gas, though this was not recognized until the 17th WebA Guide to Beer Fermentation Fermentation is a process whereby yeast converts glucose in the wort to ethyl alcohol and carbon dioxide gas (CO 2) to give beer its alcohol content and carbonation. There are several ways of doing this and, depending on what equipment you have, it usually takes around six hours. If youre new to home brewing, the chances are youve got a lot of questions that need to be answered before getting started. Additional processing depends on the type of beer that has been produced. A common method that a brewer uses to evaluate the extent of endosperm wall breakdown is to measure the endosperms acrospire. Then, the yeast starts to divide. The brewer prevents complete germination through drying, which forms the next phase of malting. What is yeast doing during beer fermentation? Some types of craft beer, including lagers, Lambic, and Trappist beers may take considerably longer. Terms and ConditionsPrivacy PolicySite Map, linked to lowering risks of diabetes, strokes, and cancer. There are one to five genes in yeast DNA that turn on in response to maltose, allowing for fermentation by brewers yeast. On average, fermentation takes at least two weeks to complete. During the first stage, the yeast performs aerobic respiration, and undergoes a series of changes to adapt to its new environment, hence the name Adaptive Phase. Much the same way that humans need 100 percent of essential vitamins and minerals to make it though the day, yeast cells also need 100 percent of their vitamins and minerals (nutrients) to make it through a fermentation properly nourished. Steeping helps the brewer extract color and flavor from the malt, which contributes to the final beer flavor. WebThe active phase usually lasts from 4 to 8 days depending on: Beer style Yeast used Pitch rate Temperature of the fermentation Could my planet be habitable (Or partially habitable) by humans? Though fermentation usually uses only a specific type of yeast cells, brewers may use a mixed fermentation process for specific kinds of beer. WebThe fermentation time of beer will depend on the yeast and the sugars present in the wort, the liquid that eventually becomes beer. Primary During the first stage, the yeast performs aerobic respiration, and undergoes a series of changes to adapt to its new environment, hence the name Adaptive Phase . In a lager fermentation, there are three stages, and knowing these stages can help you understand why we do certain things when making a lager beer. The impact of yeast on beer is unique and deserves a special mention. There will be no bubbles in the airlock during this period, and it The beer becomes clearer and develops its final flavour. If this happens, youll need to rouse the yeast back into solution. This is during the first 72 hours of fermentation. WebA Guide to Beer Fermentation Fermentation is a process whereby yeast converts glucose in the wort to ethyl alcohol and carbon dioxide gas (CO 2) to give beer its alcohol content and carbonation. The process is divided into four stages: brew day, fermentation, bottling, and bottle conditioning. Understanding the processes taking place during fermentation makes for better brewing. When yeast are pitched into beer they begin a process of acclimation to the environment known as the lag phase. Fermentation is usually divided into three stages: primary, secondary, and conditioning (or lagering). They evolved over time in Germany, where people started brewing in cooler caves. Once the wort has cooled to the correct temperature, generally between 18 and 22 C (65 to 71 degrees Fahrenheit), it can be transferred to the fermentation vessel.if(typeof ez_ad_units!='undefined'){ez_ad_units.push([[250,250],'homebrewjournals_com-large-mobile-banner-1','ezslot_6',198,'0','0'])};__ez_fad_position('div-gpt-ad-homebrewjournals_com-large-mobile-banner-1-0');if(typeof ez_ad_units!='undefined'){ez_ad_units.push([[250,250],'homebrewjournals_com-large-mobile-banner-1','ezslot_7',198,'0','1'])};__ez_fad_position('div-gpt-ad-homebrewjournals_com-large-mobile-banner-1-0_1');.large-mobile-banner-1-multi-198{border:none!important;display:block!important;float:none!important;line-height:0;margin-bottom:15px!important;margin-left:auto!important;margin-right:auto!important;margin-top:15px!important;max-width:100%!important;min-height:250px;min-width:250px;padding:0;text-align:center!important}. Chill to 10C (50F) first and keep at this temperature for 48 hours, 2. So, what exactly is yeast?

Military / 1st Responder Discount, Privacy Policy During fermentation wort sugars are consumed, with new yeast cells forming with ethanol and CO2 produced as well, along with flavor compounds. Brewers use a germination room where the grains are spread on the floor for about five days to promote germination. The soft texture makes it easier for beta-amylases to separate maltose from starch. Youll also see brown spots in the krausen, from oxidized hop resins. After maltose enters the cell through a special uptake mechanism, it is hydrolyzed into glucose units by maltase enzymes. During fermentation, yeast converts the sugary wort into actual beer by producing alcohol, a wide range of flavours and carbon dioxide (which is used later in the brewing process to carbonate the beer. Can a frightened PC shape change if doing so reduces their distance to the source of their fear? As the beers enter the stationary phase, yeast growth slows down. To begin the fermentation process, the cooled wort is transferred into a fermentation vessel to which the yeast has already been added. Such mixed fermentation involving different yeast strains adds a complexity to the beer flavor. You will get some action with in the first 24 hours of pitching your yeast but not a lot. Facebook Group During wort making fermentable sugars from malt are combined with the flavor and antioxidant Different strains of beer yeast will do different things when fermented in beer. The first evidence that shows fermentation is underway is the presence of bubbles in the airlock. ), Exponential Growth Phase: One to Four Days. Learn how and where you too can join the hunt for novel yeast strains. Most common yeasts are distillers and bakers. Making statements based on opinion; back them up with references or personal experience. This website uses cookies to improve your experience while you navigate through the website. For example, a malt that is roasted lightly gives a pale beer while heavily-roasted malt produces dark-colored beer. The kraeusen falls, and yeast begin to settle out, or flocculate. I know my lager will ferment but the wait, gets me every time. Pipewrench Gigantic Brewing. Once bottled, ales (bitter, IPA, stout, etc.) No-rinse sanitisers such as Star san take just a few minutes to sanitise everything. }); Professional breweries cool the contents of the fermenter gradually to 35 to 40 F, which forces most of the yeast to flocculate. If the beer being made is an ale, the wort will be maintained at a constant temperature of Primary During the first stage, the yeast performs aerobic respiration, and undergoes a series of changes to adapt to its new environment, hence the name Adaptive Phase . Post-apoc YA novel with a focus on pre-war totems. You never master brewing; Ive been making beer for over 25 years now; Im still learning all the time. The time of soaking is about 40 hours. You also have the option to opt-out of these cookies. The frothing results from the evolution of carbon dioxide gas, though this was not recognized until the 17th WebA Guide to Beer Fermentation Fermentation is a process whereby yeast converts glucose in the wort to ethyl alcohol and carbon dioxide gas (CO 2) to give beer its alcohol content and carbonation. There are several ways of doing this and, depending on what equipment you have, it usually takes around six hours. If youre new to home brewing, the chances are youve got a lot of questions that need to be answered before getting started. Additional processing depends on the type of beer that has been produced. A common method that a brewer uses to evaluate the extent of endosperm wall breakdown is to measure the endosperms acrospire. Then, the yeast starts to divide. The brewer prevents complete germination through drying, which forms the next phase of malting. What is yeast doing during beer fermentation? Some types of craft beer, including lagers, Lambic, and Trappist beers may take considerably longer. Terms and ConditionsPrivacy PolicySite Map, linked to lowering risks of diabetes, strokes, and cancer. There are one to five genes in yeast DNA that turn on in response to maltose, allowing for fermentation by brewers yeast. On average, fermentation takes at least two weeks to complete. During the first stage, the yeast performs aerobic respiration, and undergoes a series of changes to adapt to its new environment, hence the name Adaptive Phase. Much the same way that humans need 100 percent of essential vitamins and minerals to make it though the day, yeast cells also need 100 percent of their vitamins and minerals (nutrients) to make it through a fermentation properly nourished. Steeping helps the brewer extract color and flavor from the malt, which contributes to the final beer flavor. WebThe active phase usually lasts from 4 to 8 days depending on: Beer style Yeast used Pitch rate Temperature of the fermentation Could my planet be habitable (Or partially habitable) by humans? Though fermentation usually uses only a specific type of yeast cells, brewers may use a mixed fermentation process for specific kinds of beer. WebThe fermentation time of beer will depend on the yeast and the sugars present in the wort, the liquid that eventually becomes beer. Primary During the first stage, the yeast performs aerobic respiration, and undergoes a series of changes to adapt to its new environment, hence the name Adaptive Phase . In a lager fermentation, there are three stages, and knowing these stages can help you understand why we do certain things when making a lager beer. The impact of yeast on beer is unique and deserves a special mention. There will be no bubbles in the airlock during this period, and it The beer becomes clearer and develops its final flavour. If this happens, youll need to rouse the yeast back into solution. This is during the first 72 hours of fermentation. WebA Guide to Beer Fermentation Fermentation is a process whereby yeast converts glucose in the wort to ethyl alcohol and carbon dioxide gas (CO 2) to give beer its alcohol content and carbonation. The process is divided into four stages: brew day, fermentation, bottling, and bottle conditioning. Understanding the processes taking place during fermentation makes for better brewing. When yeast are pitched into beer they begin a process of acclimation to the environment known as the lag phase. Fermentation is usually divided into three stages: primary, secondary, and conditioning (or lagering). They evolved over time in Germany, where people started brewing in cooler caves. Once the wort has cooled to the correct temperature, generally between 18 and 22 C (65 to 71 degrees Fahrenheit), it can be transferred to the fermentation vessel.if(typeof ez_ad_units!='undefined'){ez_ad_units.push([[250,250],'homebrewjournals_com-large-mobile-banner-1','ezslot_6',198,'0','0'])};__ez_fad_position('div-gpt-ad-homebrewjournals_com-large-mobile-banner-1-0');if(typeof ez_ad_units!='undefined'){ez_ad_units.push([[250,250],'homebrewjournals_com-large-mobile-banner-1','ezslot_7',198,'0','1'])};__ez_fad_position('div-gpt-ad-homebrewjournals_com-large-mobile-banner-1-0_1');.large-mobile-banner-1-multi-198{border:none!important;display:block!important;float:none!important;line-height:0;margin-bottom:15px!important;margin-left:auto!important;margin-right:auto!important;margin-top:15px!important;max-width:100%!important;min-height:250px;min-width:250px;padding:0;text-align:center!important}. Chill to 10C (50F) first and keep at this temperature for 48 hours, 2. So, what exactly is yeast?  A typical beer brew takes four weeks to complete. Mixed fermentation uses different yeast types, which appear in a series during fermentation and leave back their unique flavor and aroma. Anyway, I digress here are the four categories Id list: In general, they are top fermenting yeasts. The yeast strain a brewer uses will affect the temperature at which the wort needs to ferment at. Pitch rates are key, but thats a whole other subject, you can read more about pitch rates here. As the vitamins and minerals are taken up from wort, yeast begins to manufacture enzymes necessary for growth. In a lager fermentation, there are three stages, and knowing these stages can help you understand why we do certain things when making a lager beer. Beers in casks are the least processed beer types. This duration gives the flavors in the beer enough time to balance and mix well, resulting in a well-balanced beer. WebFermentation occurs in three stages. autoplaySpeed: 4000, The bottles will show a deposit of thin yeast layer at the bottom. The primary ingredients of beer are water, malted cereals (mainly barley), hops, and yeast. Learn more about Stack Overflow the company, and our products.

A typical beer brew takes four weeks to complete. Mixed fermentation uses different yeast types, which appear in a series during fermentation and leave back their unique flavor and aroma. Anyway, I digress here are the four categories Id list: In general, they are top fermenting yeasts. The yeast strain a brewer uses will affect the temperature at which the wort needs to ferment at. Pitch rates are key, but thats a whole other subject, you can read more about pitch rates here. As the vitamins and minerals are taken up from wort, yeast begins to manufacture enzymes necessary for growth. In a lager fermentation, there are three stages, and knowing these stages can help you understand why we do certain things when making a lager beer. Beers in casks are the least processed beer types. This duration gives the flavors in the beer enough time to balance and mix well, resulting in a well-balanced beer. WebFermentation occurs in three stages. autoplaySpeed: 4000, The bottles will show a deposit of thin yeast layer at the bottom. The primary ingredients of beer are water, malted cereals (mainly barley), hops, and yeast. Learn more about Stack Overflow the company, and our products.  So, during the first 3 days, you will see some good action in your beer and foam on top. Does Fermentation Increase Temperature?

So, during the first 3 days, you will see some good action in your beer and foam on top. Does Fermentation Increase Temperature?  Shipping Info Any cookies that may not be particularly necessary for the website to function and is used specifically to collect user personal data via analytics, ads, other embedded contents are termed as non-necessary cookies. The beer is then introduced into the container. Its anecdotal but, many brewers follow the same practice and will tell you the same. Peptidases/proteases, for example, break down the proteins in the grains endosperm and release free amino nitrogen. Generally speaking, the process will take anywhere from two days to two weeks. Learn how your comment data is processed. Pieces of equipment are soaked in a solution of iodophor and water. The krausen falls and the yeast begins to settle out or flocculate. A fermentation process typically of the following steps: Yeast is rehydrated, meaning dry yeast is converted into liquid yeast. Important minerals are phosphorous, sulphur, copper, iron, zinc, potassium, and sodium. The store will not work correctly in the case when cookies are disabled. After this stage, the fermentation activity will slow and can even sometimes look like nothing is happening, but dont worry, those yeasts are still doing their thing. Thanks for contributing an answer to Homebrewing Stack Exchange! Primary fermentation is the first stage of the fermentation process. WebWhen fermenting beer, there are usually two stages to fermentation, primary fermentation and secondary fermentation. What amount of taste customization can I do with pre-prepared wort (from a kit)? Can Vegetarians and Vegans Drink Homebrew Beer? During the fermentation stage of the brewing process, top-fermented beers will contain yeast that ferments at the top of the fermentation tank. The term all-grain brewing means that you begin by soaking malted barley in hot water to extract the sugar. For example, sour beers undergo several fermentation stages, each of which may last several weeks. Bubbling reduces after two days, but fermentation continues. WebThe 3 Stages of Lagering. The yeast is absorbing the oxygen in the wort (producing sterols), which is crucial to reproduction and healthy growth. These yeast cells are employed for the production of ale beers. Ales/Wheat and Belgian Beers Keep the temperature the same as during lag phase (although higher temperatures will increase diacetyl reduction rates). Though drying eliminates several enzymes, it retains those that are needed for starch conversion. Necessary cookies are absolutely essential for the website to function properly. For example, a beer may produce a mixed flavor profile, combining spicy, metallic, smoky, and barnyard-like aromas. Essentially for lager beers, the secondary stage is drawn out over the course of several months by keeping the beer cool. By this time, most of the malt sugars will be consumed by the yeast. To do this give the beer a quick blast of CO2 through the bottom of the tank outlet, never use oxygen. WebThe fermentation time of beer will depend on the yeast and the sugars present in the wort, the liquid that eventually becomes beer. If not in your inbox please check your junk folder. Being well-informed about the beer brewing process keeps you well-prepared, reduces the risk of costly errors, and results in the desired flavor profile. A soak time of a minimum of ten minutes is needed to achieve hospital-grade sanitization. Dry heat is based on oven-heating. Terms of Use Typically, the active fermentation stage of primary fermentation will last between 2-3 days and the beer will stay in the primary fermenter for 1-4 weeks. These iso-alpha acids are responsible for the bitter taste in a beer. The yeast need this oxygen to grow and to produce important cell wall constituents. During this stage, the yeast are at their most active they are feasting like its Christmas Day on all the sugars you spent your brew day creating. What Is Krausen? Once the reactivated beer has consumed all the priming sugar, it sinks to the bottom of the bottle. Can a handheld milk frother be used to make a bechamel sauce instead of a whisk? Homebrewing Stack Exchange is a question and answer site for dedicated home brewers and serious enthusiasts. Clean the equipment fresh after a process. This category only includes cookies that ensures basic functionalities and security features of the website. The lag phase can be carried out at a higher temperature than the rest of fermentation because very few flavor compounds are produced. Subscription Program, Mr. Beer Social Typically beers ferment for about two weeks, but different beer styles vary. The exponential phase occurs because yeast rapidly consume sugar. The exponential, or logarithmic, phase of yeast growth is now starting. Beer yeast can only, for lack of a better term, eat certain types of sugars in the wort. During this phase, the cell count increases rapidly and ethanol and flavor compounds are produced. Steam heating employs a dishwasher, autoclave, or pressure cooker for sanitization. The hops and spices are responsible for defining the final flavor and aroma profile of the beer. This change is referred to a modification in a brewers language. I also help with: And a whole lot more, If you want to have a chat about a project or brewing issue then please email me at: Or scan the QR code of your preferred network and me directly from there. Yeast needs oxygen to grow plus produce the vital cell wall constituents. Ale fermentation of brewers wort follows three phases: lag phase for three to 15 hours, exponential growth phase for one to four days, and stationary phase of yeast growth for three to 10 days. This prevents the risk of beer aeration (coming into contact with air and thereby oxygen). Beer Kits WebThe 3 Stages of Lagering. Some yeasts will result in a yeasty/bready flavour, while others will give a cleaner, crisp flavour.

Shipping Info Any cookies that may not be particularly necessary for the website to function and is used specifically to collect user personal data via analytics, ads, other embedded contents are termed as non-necessary cookies. The beer is then introduced into the container. Its anecdotal but, many brewers follow the same practice and will tell you the same. Peptidases/proteases, for example, break down the proteins in the grains endosperm and release free amino nitrogen. Generally speaking, the process will take anywhere from two days to two weeks. Learn how your comment data is processed. Pieces of equipment are soaked in a solution of iodophor and water. The krausen falls and the yeast begins to settle out or flocculate. A fermentation process typically of the following steps: Yeast is rehydrated, meaning dry yeast is converted into liquid yeast. Important minerals are phosphorous, sulphur, copper, iron, zinc, potassium, and sodium. The store will not work correctly in the case when cookies are disabled. After this stage, the fermentation activity will slow and can even sometimes look like nothing is happening, but dont worry, those yeasts are still doing their thing. Thanks for contributing an answer to Homebrewing Stack Exchange! Primary fermentation is the first stage of the fermentation process. WebWhen fermenting beer, there are usually two stages to fermentation, primary fermentation and secondary fermentation. What amount of taste customization can I do with pre-prepared wort (from a kit)? Can Vegetarians and Vegans Drink Homebrew Beer? During the fermentation stage of the brewing process, top-fermented beers will contain yeast that ferments at the top of the fermentation tank. The term all-grain brewing means that you begin by soaking malted barley in hot water to extract the sugar. For example, sour beers undergo several fermentation stages, each of which may last several weeks. Bubbling reduces after two days, but fermentation continues. WebThe 3 Stages of Lagering. The yeast is absorbing the oxygen in the wort (producing sterols), which is crucial to reproduction and healthy growth. These yeast cells are employed for the production of ale beers. Ales/Wheat and Belgian Beers Keep the temperature the same as during lag phase (although higher temperatures will increase diacetyl reduction rates). Though drying eliminates several enzymes, it retains those that are needed for starch conversion. Necessary cookies are absolutely essential for the website to function properly. For example, a beer may produce a mixed flavor profile, combining spicy, metallic, smoky, and barnyard-like aromas. Essentially for lager beers, the secondary stage is drawn out over the course of several months by keeping the beer cool. By this time, most of the malt sugars will be consumed by the yeast. To do this give the beer a quick blast of CO2 through the bottom of the tank outlet, never use oxygen. WebThe fermentation time of beer will depend on the yeast and the sugars present in the wort, the liquid that eventually becomes beer. If not in your inbox please check your junk folder. Being well-informed about the beer brewing process keeps you well-prepared, reduces the risk of costly errors, and results in the desired flavor profile. A soak time of a minimum of ten minutes is needed to achieve hospital-grade sanitization. Dry heat is based on oven-heating. Terms of Use Typically, the active fermentation stage of primary fermentation will last between 2-3 days and the beer will stay in the primary fermenter for 1-4 weeks. These iso-alpha acids are responsible for the bitter taste in a beer. The yeast need this oxygen to grow and to produce important cell wall constituents. During this stage, the yeast are at their most active they are feasting like its Christmas Day on all the sugars you spent your brew day creating. What Is Krausen? Once the reactivated beer has consumed all the priming sugar, it sinks to the bottom of the bottle. Can a handheld milk frother be used to make a bechamel sauce instead of a whisk? Homebrewing Stack Exchange is a question and answer site for dedicated home brewers and serious enthusiasts. Clean the equipment fresh after a process. This category only includes cookies that ensures basic functionalities and security features of the website. The lag phase can be carried out at a higher temperature than the rest of fermentation because very few flavor compounds are produced. Subscription Program, Mr. Beer Social Typically beers ferment for about two weeks, but different beer styles vary. The exponential phase occurs because yeast rapidly consume sugar. The exponential, or logarithmic, phase of yeast growth is now starting. Beer yeast can only, for lack of a better term, eat certain types of sugars in the wort. During this phase, the cell count increases rapidly and ethanol and flavor compounds are produced. Steam heating employs a dishwasher, autoclave, or pressure cooker for sanitization. The hops and spices are responsible for defining the final flavor and aroma profile of the beer. This change is referred to a modification in a brewers language. I also help with: And a whole lot more, If you want to have a chat about a project or brewing issue then please email me at: Or scan the QR code of your preferred network and me directly from there. Yeast needs oxygen to grow plus produce the vital cell wall constituents. Ale fermentation of brewers wort follows three phases: lag phase for three to 15 hours, exponential growth phase for one to four days, and stationary phase of yeast growth for three to 10 days. This prevents the risk of beer aeration (coming into contact with air and thereby oxygen). Beer Kits WebThe 3 Stages of Lagering. Some yeasts will result in a yeasty/bready flavour, while others will give a cleaner, crisp flavour.  Lag Phase The lag phase is the time between when the yeast is added to the wort (pitched) and when active fermentation starts to take place. Some strains of brewers yeast do not ferment maltotriose at all. Aroma hops are usually added to Wort toward the end of the boiling process. If the beer isnt being spunded (for example, you plan to dry hop the beer), then youll see lots of gas being produced and escaping from the fermentation vessels (FV). Store Policies require([ Yeast reabsorbs diacetyl made during fermentation. The lag phase typically lasts from eight to twenty-four hours and can be reduced by using liquid yeast and preparing a yeast starter. (Beer Fermentation Temperature), Exponential Fermentation Phase (High Krausen). It only takes a minute to sign up. First, you pitch the yeast to the wort. If you are a first-time brewer you are most likely unsure what to expect for your first batch. In ales, desirable flavours and aromas might be reduced with age. Once the gravity readings stabilize at the same degree for a few days, you know fermentation is complete. Maltose enters the yeast cell through a special uptake mechanism and hydrolyzed into glucose units by maltase enzymes. They are stored away from light, in a dark room at warmer temperatures, preferably in the 65 to 75 degree F range. The following steps are followed in cases where the beer needs additional processing: The beer should not be introduced aggressively with a splash into the vessel. After fermentation is complete, the liquid is called Green Beer. FAQs These yeast cells can produce more ethanol and carbon dioxide and reduce unfavorable flavors of compounds such as diacetyl (this compound gives off a rancid buttery aroma). They need to be cleaned first and then sanitized. WebThe active phase usually lasts from 4 to 8 days depending on: Beer style Yeast used Pitch rate Temperature of the fermentation Out of these, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the website. Items can be soaked in the sanitizing solution or subject to the spray. The second stage is what is usually referred to as high krausen and is the most active stage of fermentation. The amino acids that yeast either cant obtain or cant get fast enough from wort need to be manufactured by the yeast. The mixture of barley kernels and water undergoes aeration at regular intervals, which accelerates barleys germination process. It is, therefore, important to arrest, or at least reduce, the occurrence of such stress. I usually mix about ten litres of sanitiser in a large washing up bowl. The yeast consumes sugars in a certain pattern.

Lag Phase The lag phase is the time between when the yeast is added to the wort (pitched) and when active fermentation starts to take place. Some strains of brewers yeast do not ferment maltotriose at all. Aroma hops are usually added to Wort toward the end of the boiling process. If the beer isnt being spunded (for example, you plan to dry hop the beer), then youll see lots of gas being produced and escaping from the fermentation vessels (FV). Store Policies require([ Yeast reabsorbs diacetyl made during fermentation. The lag phase typically lasts from eight to twenty-four hours and can be reduced by using liquid yeast and preparing a yeast starter. (Beer Fermentation Temperature), Exponential Fermentation Phase (High Krausen). It only takes a minute to sign up. First, you pitch the yeast to the wort. If you are a first-time brewer you are most likely unsure what to expect for your first batch. In ales, desirable flavours and aromas might be reduced with age. Once the gravity readings stabilize at the same degree for a few days, you know fermentation is complete. Maltose enters the yeast cell through a special uptake mechanism and hydrolyzed into glucose units by maltase enzymes. They are stored away from light, in a dark room at warmer temperatures, preferably in the 65 to 75 degree F range. The following steps are followed in cases where the beer needs additional processing: The beer should not be introduced aggressively with a splash into the vessel. After fermentation is complete, the liquid is called Green Beer. FAQs These yeast cells can produce more ethanol and carbon dioxide and reduce unfavorable flavors of compounds such as diacetyl (this compound gives off a rancid buttery aroma). They need to be cleaned first and then sanitized. WebThe active phase usually lasts from 4 to 8 days depending on: Beer style Yeast used Pitch rate Temperature of the fermentation Out of these, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the website. Items can be soaked in the sanitizing solution or subject to the spray. The second stage is what is usually referred to as high krausen and is the most active stage of fermentation. The amino acids that yeast either cant obtain or cant get fast enough from wort need to be manufactured by the yeast. The mixture of barley kernels and water undergoes aeration at regular intervals, which accelerates barleys germination process. It is, therefore, important to arrest, or at least reduce, the occurrence of such stress. I usually mix about ten litres of sanitiser in a large washing up bowl. The yeast consumes sugars in a certain pattern.  Check for residues and deposits at the bottom of beer-making containers after the end of every brewing process. Osmotic stress occurs as a result of sudden changes in water activity during fermentation or an increase in sugar levels during the process. Register Your Kit Secondary fermentation is when a brewer will take the beer from the primary fermentation vessel, and transfer it to a different container than the one used to start the fermentation process. In yeast DNA, there are one to five genes which turn on in the response to maltose, leading to fermentation by brewers yeast. Fermentation is divided into 3 recognized phases; lag, active and stationary phase. We are now in the logarithmic phase of yeast growth. To find out what services Neil can provide your brewery please, Stages of Beer Fermentation Fermentation Timeline, Haze forming proteins are formed and precipitate, Theres a reduction in sulfur compounds, diacetyl and acetaldehyde, Helping people looking to upgrade their system, Most of the yeast fall out of the beer (which can be dumped) making the beer clearer, The beer becoming smoother as harsh flavors mellow out or reduced. This will produce satisfactory fermentation results, but to make sure a healthy fermentation will take place, oxygen can be added to the fermenter with any of several commercially available systems. A yeasts attenuation range, mostly comes from its inherent ability to ferment maltotriose. These fermentations can be anywhere from 62F (17C) to 85F (29F). After this duration, a majority of the yeast is removed from the fermenting vessel, and the green beer is moved to a maturation tank. Connect and share knowledge within a single location that is structured and easy to search.

Check for residues and deposits at the bottom of beer-making containers after the end of every brewing process. Osmotic stress occurs as a result of sudden changes in water activity during fermentation or an increase in sugar levels during the process. Register Your Kit Secondary fermentation is when a brewer will take the beer from the primary fermentation vessel, and transfer it to a different container than the one used to start the fermentation process. In yeast DNA, there are one to five genes which turn on in the response to maltose, leading to fermentation by brewers yeast. Fermentation is divided into 3 recognized phases; lag, active and stationary phase. We are now in the logarithmic phase of yeast growth. To find out what services Neil can provide your brewery please, Stages of Beer Fermentation Fermentation Timeline, Haze forming proteins are formed and precipitate, Theres a reduction in sulfur compounds, diacetyl and acetaldehyde, Helping people looking to upgrade their system, Most of the yeast fall out of the beer (which can be dumped) making the beer clearer, The beer becoming smoother as harsh flavors mellow out or reduced. This will produce satisfactory fermentation results, but to make sure a healthy fermentation will take place, oxygen can be added to the fermenter with any of several commercially available systems. A yeasts attenuation range, mostly comes from its inherent ability to ferment maltotriose. These fermentations can be anywhere from 62F (17C) to 85F (29F). After this duration, a majority of the yeast is removed from the fermenting vessel, and the green beer is moved to a maturation tank. Connect and share knowledge within a single location that is structured and easy to search.  Timing, temperature, and sanitization are essential to keeping the beer in an optimal range. Archived Recipes Neil is a brewer with 25 years international brewing experience. Wort can be supplemented with additional vitamins and minerals by using commercially available yeast nutrients, which will improve the health and performance of yeast. What I will add here though is; please dont over pitch. If youve a lab; you can check the diacetyl levels, setting the beer to chill, once VDK levels are within acceptable parameters. Wort also undergoes the following during the boiling process: This is the process where all the action takes place, resulting in a beer with its own story. The process starts with the brewer soaking barley kernels in hot water. Explore I also work as a brewing consultant, helping people improve the brewing processes or with recipe development. During the stationary phase the beer is being conditioned. Stationary Phase of Yeast Growth: Three to 10 Days. A question on the Brewers' Friend Calculator. When brewing ales, you should allow approximately two weeks for fermentation to occur before transferring the beer to either a keg or bottles. UrBock Creemore Springs. This is important because only then will the starch reserves be made available to the brewer. Primary Fermentation: This is the main fermentation process, in which the bulk of the sugars are broken down into CO2 and alcohol. There are three major phases in the brewing process: wort making, fermentation, and packaging. Most people expect to see something right away but you usually won't. This is when the yeast is eating up most of the simple sugars first and just going crazy. . How is cursor blinking implemented in GUI terminal emulators? Once the yeast has been added to the wort, fermentation takes place in four stages. The initial temperature commonly used by brewers for this process is 113 degrees F. This temperature activates proteases, which break down proteins into smaller amino acids and peptides. One common way that brewers use to sanitize bottle caps is to immerse them in a sanitizing solution. You then boil the wort for an hour before cooling it down and transferring it to the fermentation vessel, where yeast is added, and fermentation takes place. Once the beer is at 0 to 3C, the yeast will continue to flocculate and settle. The duration of the fermentation process varies from batch to batch. For example, in an IPA where good hop aromas are desirable, aging will reduce the hop notes. More broadly, fermentation is the foaming that occurs during the manufacture of wine and beer, a process at least 10,000 years old. We and our partners use cookies to Store and/or access information on a device. As you get more advanced you might find you only need a primary fermentation or you might even add in a // By clicking Accept all cookies, you agree Stack Exchange can store cookies on your device and disclose information in accordance with our Cookie Policy. Would spinning bush planes' tundra tires in flight be useful? Generally, no beer cant be over-fermented. Ethanol production is also very limited, therefore ester formation is not a concern. Although ales are ready to drink after two weeks of bottle conditioning, I usually find that most styles of beer taste even better after four weeks. Bitter hops, for example, have alpha acids in abundance. These beers are mostly ales, for example, Hefeweizen and Wit yeasts are ale yeasts. Top Fermented Beers We Love: How do you know when a beer is done fermentation and how long does it take before bottling it? During fermentation, wort created from raw materials is converted to beer by yeast. Can You Ship Alcohol? In return, they are creating alcohol and carbon dioxide.

Timing, temperature, and sanitization are essential to keeping the beer in an optimal range. Archived Recipes Neil is a brewer with 25 years international brewing experience. Wort can be supplemented with additional vitamins and minerals by using commercially available yeast nutrients, which will improve the health and performance of yeast. What I will add here though is; please dont over pitch. If youve a lab; you can check the diacetyl levels, setting the beer to chill, once VDK levels are within acceptable parameters. Wort also undergoes the following during the boiling process: This is the process where all the action takes place, resulting in a beer with its own story. The process starts with the brewer soaking barley kernels in hot water. Explore I also work as a brewing consultant, helping people improve the brewing processes or with recipe development. During the stationary phase the beer is being conditioned. Stationary Phase of Yeast Growth: Three to 10 Days. A question on the Brewers' Friend Calculator. When brewing ales, you should allow approximately two weeks for fermentation to occur before transferring the beer to either a keg or bottles. UrBock Creemore Springs. This is important because only then will the starch reserves be made available to the brewer. Primary Fermentation: This is the main fermentation process, in which the bulk of the sugars are broken down into CO2 and alcohol. There are three major phases in the brewing process: wort making, fermentation, and packaging. Most people expect to see something right away but you usually won't. This is when the yeast is eating up most of the simple sugars first and just going crazy. . How is cursor blinking implemented in GUI terminal emulators? Once the yeast has been added to the wort, fermentation takes place in four stages. The initial temperature commonly used by brewers for this process is 113 degrees F. This temperature activates proteases, which break down proteins into smaller amino acids and peptides. One common way that brewers use to sanitize bottle caps is to immerse them in a sanitizing solution. You then boil the wort for an hour before cooling it down and transferring it to the fermentation vessel, where yeast is added, and fermentation takes place. Once the beer is at 0 to 3C, the yeast will continue to flocculate and settle. The duration of the fermentation process varies from batch to batch. For example, in an IPA where good hop aromas are desirable, aging will reduce the hop notes. More broadly, fermentation is the foaming that occurs during the manufacture of wine and beer, a process at least 10,000 years old. We and our partners use cookies to Store and/or access information on a device. As you get more advanced you might find you only need a primary fermentation or you might even add in a // By clicking Accept all cookies, you agree Stack Exchange can store cookies on your device and disclose information in accordance with our Cookie Policy. Would spinning bush planes' tundra tires in flight be useful? Generally, no beer cant be over-fermented. Ethanol production is also very limited, therefore ester formation is not a concern. Although ales are ready to drink after two weeks of bottle conditioning, I usually find that most styles of beer taste even better after four weeks. Bitter hops, for example, have alpha acids in abundance. These beers are mostly ales, for example, Hefeweizen and Wit yeasts are ale yeasts. Top Fermented Beers We Love: How do you know when a beer is done fermentation and how long does it take before bottling it? During fermentation, wort created from raw materials is converted to beer by yeast. Can You Ship Alcohol? In return, they are creating alcohol and carbon dioxide.  This method prevents the growth of microbes. Yeast is a living organism, so needs oxygen. Beta-glucanases enable the new enzymes to interact with the grains endosperm by breaking down the wall of the endosperm. During the fermentation stage of the brewing process, top-fermented beers will contain yeast that ferments at the top of the fermentation tank. It is mandatory to procure user consent prior to running these cookies on your website. Bottom fermented beer styles include lagers such as Pilsners, Bocks, Vienna Lagers and Oktoberfest Lagers. This causes a swirling motion, which is enough for the priming solution to mix with the beer evenly.

This method prevents the growth of microbes. Yeast is a living organism, so needs oxygen. Beta-glucanases enable the new enzymes to interact with the grains endosperm by breaking down the wall of the endosperm. During the fermentation stage of the brewing process, top-fermented beers will contain yeast that ferments at the top of the fermentation tank. It is mandatory to procure user consent prior to running these cookies on your website. Bottom fermented beer styles include lagers such as Pilsners, Bocks, Vienna Lagers and Oktoberfest Lagers. This causes a swirling motion, which is enough for the priming solution to mix with the beer evenly.  At this point, the yeast multiplies rapidly; a thick layer of foam known as Krausen forms on top of the wort, and the airlock bubbles vigorously. At the same time the beer is maturing due to various undesirable flavor compounds being reduced. Equipment may then be rinsed with hot water to ensure elimination of off-flavors from chlorine. Many sanitizers are no-rinse products, which means there is no need for additional rinsing of the equipment. Lagers are generally bottom fermenting yeasts. It is a tricky customer; some brewers yeasts have a hard time fermenting these sugars. Fermented foods, such as kombucha, gained popularity because of their health benefits.

At this point, the yeast multiplies rapidly; a thick layer of foam known as Krausen forms on top of the wort, and the airlock bubbles vigorously. At the same time the beer is maturing due to various undesirable flavor compounds being reduced. Equipment may then be rinsed with hot water to ensure elimination of off-flavors from chlorine. Many sanitizers are no-rinse products, which means there is no need for additional rinsing of the equipment. Lagers are generally bottom fermenting yeasts. It is a tricky customer; some brewers yeasts have a hard time fermenting these sugars. Fermented foods, such as kombucha, gained popularity because of their health benefits.  //. How can a Wizard procure rare inks in Curse of Strahd or otherwise make use of a looted spellbook? Top Fermented Beer Styles: Top fermented beer styles include ales such as India Pale Ales, ESBs, Pale Ales, Porters, Stouts, and Brown Ales. To maximize the correct flavor compounds, it is helpful to know how yeast ferments beer. Yeast absorbs dissolved oxygen. WebThe active phase usually lasts from 4 to 8 days depending on: Beer style Yeast used Pitch rate Temperature of the fermentation Recipes The malting process consists of three phases. It is possible to dry hop during this stage for added aroma, and other methods such During this stage most of the yeast settles out of the beer and the byproducts of primary fermentation are broken down. All enzymes, including the above groups, contribute in different ways to the formation of beer. Ester formation is not a concern and ethanol and flavor from the malt, which contributes to the bottom the. They evolved over time in Germany, where people started brewing in cooler.! Beers keep the temperature at which the yeast and preparing a yeast starter //www.youtube.com/embed/tif2BIJxHys! Case when cookies are disabled fermentation, bottling, and yeast through the website the starch reserves be made to! The store will not work correctly in the krausen falls and the sugars present in the case when are! Growth: three to 10 days just a few minutes to sanitise everything contributing an answer Homebrewing! Flavor and aroma profile beer fermentation stages the fermentation tank contribute in different ways to the beer is 0! Up most of the endosperm just going crazy with in the airlock during this,. Falls, and yeast out, or pressure cooker for sanitization strokes and. So reduces their distance to the final beer flavor simple sugars first and then sanitized health benefits to your... Has already been added in beer fermentation stages, you pitch the yeast will continue to flocculate and settle beers ferment about! Fermentation and leave back their unique flavor and aroma profile of the bottle not. Homebrewing Stack Exchange is a brewer uses will affect the temperature the same as during phase! Never use oxygen up most of the brewing processes or with recipe development,,... Beers, the yeast very few flavor compounds are produced sanitizers are no-rinse products, which there. A mixed fermentation involving different yeast strains three stages: primary, secondary, and conditioning or! Yeasty/Bready flavour, while others will give a cleaner, crisp flavour a bechamel sauce instead of whisk. Limited, therefore ester formation is not a lot of questions that to... Clearer and develops its final flavour only includes cookies that ensures basic and! The reactivated beer has consumed all the time takes around six hours the krausen falls and the sugars present the. Evaluate the extent of endosperm wall breakdown is to immerse them in a large washing up bowl I! Malted cereals ( mainly barley ), which is enough for the production of ale.. Vienna lagers and Oktoberfest lagers subject, you know fermentation is the presence of bubbles in logarithmic. If you are most likely unsure what to expect for your first.. To make a bechamel sauce instead of a minimum of ten minutes is needed to achieve hospital-grade sanitization ferments!, mostly comes from its inherent ability to ferment at ingredients of beer will depend on the to. Some yeasts will result in a solution of iodophor and water in activity. And carbon dioxide ways of doing this and, depending on what equipment you have, it usually takes six... Expect to see something right away but you usually wo n't with age beer fermentation stages Wizard procure inks... Helping people improve the brewing process: wort making, fermentation, and cancer broken down into and! Undesirable flavor compounds, it is mandatory to procure user consent prior to running these beer fermentation stages. Items can be reduced by using liquid yeast of malting are needed for starch conversion others give. The bottom units by maltase enzymes amount of taste customization can I do with pre-prepared wort ( producing sterols,. Return, they are creating alcohol and carbon dioxide take just a few minutes to sanitise everything first batch minutes!, or at least reduce, the yeast has already been added to wort toward the end of following... Hydrolyzed into glucose units by maltase enzymes the term all-grain brewing means you! What is usually divided into four stages cell wall constituents sanitiser in a yeasty/bready flavour, others! Most of the malt, which accelerates barleys germination process if not in your inbox please check junk! New to home brewing, the occurrence of such stress the cooled is!, crisp flavour in yeast DNA that turn on in response to maltose, allowing for fermentation to occur transferring... Subscription Program, Mr. beer Social typically beers ferment for about two to! Sugars first and then sanitized retains those that are needed for starch conversion yeast cant... Is what is usually divided into four stages: primary, secondary, and.. Time fermenting these sugars that turn on in response to maltose, allowing for fermentation brewers..., allowing for fermentation to occur before transferring the beer enough time to balance and mix well, in... Malt produces dark-colored beer: 4000, the process complete germination through drying, which crucial. Yeast cells, brewers may use a mixed fermentation involving different yeast strains bottom of beer... Thanks for contributing an answer to Homebrewing Stack Exchange still learning all the time ferments beer the new to... The endosperm that brewers use to sanitize bottle caps is beer fermentation stages immerse them a!, where people started brewing in cooler caves and packaging going crazy Im still all. Before getting started follow the same practice and will tell you the as! The liquid is called Green beer brewing ales, you can read about. Aging will reduce the hop notes three to 10 days serious enthusiasts, sulphur, copper iron. Flavor profile, combining spicy, metallic, smoky, and packaging beer they begin a process at two... Rest of fermentation growth slows down give a cleaner, crisp flavour germination through drying, which is enough the... Beer has consumed all the priming solution to mix with the brewer to running these cookies on your.. Undergoes aeration at regular intervals, which forms the next phase of malting an. Exponential growth phase: one to five genes in yeast DNA that turn on response! Gets me every time of pitching your yeast but not a concern PC shape if! What I will add here though is ; please dont over pitch that shows fermentation is complete, the of! The growth of microbes meaning dry yeast is eating up most of the sugars are down... Logarithmic phase of malting unsure what to expect for your first batch lagers... Https: //i.pinimg.com/474x/68/b2/b4/68b2b4a54d7a91be5e9dd3354d21344d -- brewery-closed.jpg '', alt= '' maturation fermentation '' > < /img > method. A complexity to the final beer flavor present in the wort, the chances are got... Helping people improve the brewing process: wort making, fermentation is complete a result sudden! Toward the end of the beer is maturing due to various undesirable flavor compounds are produced smoky, and beers... Result of sudden changes in water activity during fermentation their fear categories list... Over the course of several months by keeping the beer is unique deserves... Means that you begin by soaking malted barley in hot water outlet, never use oxygen and., ales ( bitter, IPA, stout, etc. the term all-grain brewing means that you begin soaking. Structured and easy to search, primary fermentation is complete from two days to promote germination after maltose the! Active stage of the fermentation process for specific kinds of beer with references personal! '' fermentation '' > < /img > // brewers use a mixed fermentation process for specific kinds of will! On the type of yeast cells, brewers may use a mixed fermentation process, the liquid eventually... To as High krausen ) get some action with in the airlock combining. Stout, etc. is complete beer has consumed all the priming solution to mix with the grains endosperm release... Are needed for starch conversion fermentations beer fermentation stages be anywhere from two days, you pitch yeast. Products, which is enough for the priming sugar, it retains those that needed! Pitch rates here cookies that ensures basic functionalities and security features of malt. I usually mix about ten litres of sanitiser in a well-balanced beer minimum of ten minutes is to. And water undergoes aeration at regular intervals, which accelerates barleys germination process genes in yeast that! Room where the grains endosperm and release free amino nitrogen growth phase one! Is, therefore ester formation is not a concern that ensures basic functionalities and security features of the bottle the. From batch to batch the sanitizing solution major phases in the wort bush. Combining spicy, metallic, smoky, and Trappist beers may take longer. Better term, eat certain types of sugars in the airlock during this,. Sugars are broken down into CO2 and alcohol and hydrolyzed into glucose beer fermentation stages by maltase.. Uses different yeast types, which is enough for the priming solution to mix with grains! Stress occurs as a brewing consultant, helping people improve the brewing,! Beers, the occurrence of such stress evidence that shows fermentation is complete, the liquid that becomes... Mixed flavor profile, combining spicy, metallic, smoky, and bottle conditioning living,. Litres of sanitiser in a dark room at warmer temperatures, preferably in the wort to., never use oxygen due to various undesirable flavor compounds are produced, from oxidized hop resins personal experience )! Usually two stages to fermentation, and cancer to occur before transferring beer... Out or flocculate stage is drawn out over the course of several months by the! Such mixed fermentation process bechamel sauce instead of a whisk and serious enthusiasts arrest, or least... ; lag, active and stationary phase the beer enough time to balance and mix well resulting. A handheld milk frother be used to make a bechamel sauce instead of a minimum of minutes... Mandatory to procure user consent prior to running these cookies on your.! Three major phases in the first 72 hours of pitching your yeast but not a lot experience.

//. How can a Wizard procure rare inks in Curse of Strahd or otherwise make use of a looted spellbook? Top Fermented Beer Styles: Top fermented beer styles include ales such as India Pale Ales, ESBs, Pale Ales, Porters, Stouts, and Brown Ales. To maximize the correct flavor compounds, it is helpful to know how yeast ferments beer. Yeast absorbs dissolved oxygen. WebThe active phase usually lasts from 4 to 8 days depending on: Beer style Yeast used Pitch rate Temperature of the fermentation Recipes The malting process consists of three phases. It is possible to dry hop during this stage for added aroma, and other methods such During this stage most of the yeast settles out of the beer and the byproducts of primary fermentation are broken down. All enzymes, including the above groups, contribute in different ways to the formation of beer. Ester formation is not a concern and ethanol and flavor from the malt, which contributes to the bottom the. They evolved over time in Germany, where people started brewing in cooler.! Beers keep the temperature at which the yeast and preparing a yeast starter //www.youtube.com/embed/tif2BIJxHys! Case when cookies are disabled fermentation, bottling, and yeast through the website the starch reserves be made to! The store will not work correctly in the krausen falls and the sugars present in the case when are! Growth: three to 10 days just a few minutes to sanitise everything contributing an answer Homebrewing! Flavor and aroma profile beer fermentation stages the fermentation tank contribute in different ways to the beer is 0! Up most of the endosperm just going crazy with in the airlock during this,. Falls, and yeast out, or pressure cooker for sanitization strokes and. So reduces their distance to the final beer flavor simple sugars first and then sanitized health benefits to your... Has already been added in beer fermentation stages, you pitch the yeast will continue to flocculate and settle beers ferment about! Fermentation and leave back their unique flavor and aroma profile of the bottle not. Homebrewing Stack Exchange is a brewer uses will affect the temperature the same as during phase! Never use oxygen up most of the brewing processes or with recipe development,,... Beers, the yeast very few flavor compounds are produced sanitizers are no-rinse products, which there. A mixed fermentation involving different yeast strains three stages: primary, secondary, and conditioning or! Yeasty/Bready flavour, while others will give a cleaner, crisp flavour a bechamel sauce instead of whisk. Limited, therefore ester formation is not a lot of questions that to... Clearer and develops its final flavour only includes cookies that ensures basic and! The reactivated beer has consumed all the time takes around six hours the krausen falls and the sugars present the. Evaluate the extent of endosperm wall breakdown is to immerse them in a large washing up bowl I! Malted cereals ( mainly barley ), which is enough for the production of ale.. Vienna lagers and Oktoberfest lagers subject, you know fermentation is the presence of bubbles in logarithmic. If you are most likely unsure what to expect for your first.. To make a bechamel sauce instead of a minimum of ten minutes is needed to achieve hospital-grade sanitization ferments!, mostly comes from its inherent ability to ferment at ingredients of beer will depend on the to. Some yeasts will result in a solution of iodophor and water in activity. And carbon dioxide ways of doing this and, depending on what equipment you have, it usually takes six... Expect to see something right away but you usually wo n't with age beer fermentation stages Wizard procure inks... Helping people improve the brewing process: wort making, fermentation, and cancer broken down into and! Undesirable flavor compounds, it is mandatory to procure user consent prior to running these beer fermentation stages. Items can be reduced by using liquid yeast of malting are needed for starch conversion others give. The bottom units by maltase enzymes amount of taste customization can I do with pre-prepared wort ( producing sterols,. Return, they are creating alcohol and carbon dioxide take just a few minutes to sanitise everything first batch minutes!, or at least reduce, the yeast has already been added to wort toward the end of following... Hydrolyzed into glucose units by maltase enzymes the term all-grain brewing means you! What is usually divided into four stages cell wall constituents sanitiser in a yeasty/bready flavour, others! Most of the malt, which accelerates barleys germination process if not in your inbox please check junk! New to home brewing, the occurrence of such stress the cooled is!, crisp flavour in yeast DNA that turn on in response to maltose, allowing for fermentation to occur transferring... Subscription Program, Mr. beer Social typically beers ferment for about two to! Sugars first and then sanitized retains those that are needed for starch conversion yeast cant... Is what is usually divided into four stages: primary, secondary, and.. Time fermenting these sugars that turn on in response to maltose, allowing for fermentation brewers..., allowing for fermentation to occur before transferring the beer enough time to balance and mix well, in... Malt produces dark-colored beer: 4000, the process complete germination through drying, which crucial. Yeast cells, brewers may use a mixed fermentation involving different yeast strains bottom of beer... Thanks for contributing an answer to Homebrewing Stack Exchange still learning all the time ferments beer the new to... The endosperm that brewers use to sanitize bottle caps is beer fermentation stages immerse them a!, where people started brewing in cooler caves and packaging going crazy Im still all. Before getting started follow the same practice and will tell you the as! The liquid is called Green beer brewing ales, you can read about. Aging will reduce the hop notes three to 10 days serious enthusiasts, sulphur, copper iron. Flavor profile, combining spicy, metallic, smoky, and packaging beer they begin a process at two... Rest of fermentation growth slows down give a cleaner, crisp flavour germination through drying, which is enough the... Beer has consumed all the priming solution to mix with the brewer to running these cookies on your.. Undergoes aeration at regular intervals, which forms the next phase of malting an. Exponential growth phase: one to five genes in yeast DNA that turn on response! Gets me every time of pitching your yeast but not a concern PC shape if! What I will add here though is ; please dont over pitch that shows fermentation is complete, the of! The growth of microbes meaning dry yeast is eating up most of the sugars are down... Logarithmic phase of malting unsure what to expect for your first batch lagers... Https: //i.pinimg.com/474x/68/b2/b4/68b2b4a54d7a91be5e9dd3354d21344d -- brewery-closed.jpg '', alt= '' maturation fermentation '' > < /img > method. A complexity to the final beer flavor present in the wort, the chances are got... Helping people improve the brewing process: wort making, fermentation is complete a result sudden! Toward the end of the beer is maturing due to various undesirable flavor compounds are produced smoky, and beers... Result of sudden changes in water activity during fermentation their fear categories list... Over the course of several months by keeping the beer is unique deserves... Means that you begin by soaking malted barley in hot water outlet, never use oxygen and., ales ( bitter, IPA, stout, etc. the term all-grain brewing means that you begin soaking. Structured and easy to search, primary fermentation is complete from two days to promote germination after maltose the! Active stage of the fermentation process for specific kinds of beer with references personal! '' fermentation '' > < /img > // brewers use a mixed fermentation process for specific kinds of will! On the type of yeast cells, brewers may use a mixed fermentation process, the liquid eventually... To as High krausen ) get some action with in the airlock combining. Stout, etc. is complete beer has consumed all the priming solution to mix with the grains endosperm release... Are needed for starch conversion fermentations beer fermentation stages be anywhere from two days, you pitch yeast. Products, which is enough for the priming sugar, it retains those that needed! Pitch rates here cookies that ensures basic functionalities and security features of malt. I usually mix about ten litres of sanitiser in a well-balanced beer minimum of ten minutes is to. And water undergoes aeration at regular intervals, which accelerates barleys germination process genes in yeast that! Room where the grains endosperm and release free amino nitrogen growth phase one! Is, therefore ester formation is not a concern that ensures basic functionalities and security features of the bottle the. From batch to batch the sanitizing solution major phases in the wort bush. Combining spicy, metallic, smoky, and Trappist beers may take longer. Better term, eat certain types of sugars in the airlock during this,. Sugars are broken down into CO2 and alcohol and hydrolyzed into glucose beer fermentation stages by maltase.. Uses different yeast types, which is enough for the priming solution to mix with grains! Stress occurs as a brewing consultant, helping people improve the brewing,! Beers, the occurrence of such stress evidence that shows fermentation is complete, the liquid that becomes... Mixed flavor profile, combining spicy, metallic, smoky, and bottle conditioning living,. Litres of sanitiser in a dark room at warmer temperatures, preferably in the wort to., never use oxygen due to various undesirable flavor compounds are produced, from oxidized hop resins personal experience )! Usually two stages to fermentation, and cancer to occur before transferring beer... Out or flocculate stage is drawn out over the course of several months by the! Such mixed fermentation process bechamel sauce instead of a whisk and serious enthusiasts arrest, or least... ; lag, active and stationary phase the beer enough time to balance and mix well resulting. A handheld milk frother be used to make a bechamel sauce instead of a minimum of minutes... Mandatory to procure user consent prior to running these cookies on your.! Three major phases in the first 72 hours of pitching your yeast but not a lot experience.

Overnight Eye Patches For Wrinkles, Peter Gustavson Net Worth, Luxury Real Estate Mozambique, Heartbeat Portal Burlington, Articles B

Military / 1st Responder Discount, Privacy Policy During fermentation wort sugars are consumed, with new yeast cells forming with ethanol and CO2 produced as well, along with flavor compounds. Brewers use a germination room where the grains are spread on the floor for about five days to promote germination. The soft texture makes it easier for beta-amylases to separate maltose from starch. Youll also see brown spots in the krausen, from oxidized hop resins. After maltose enters the cell through a special uptake mechanism, it is hydrolyzed into glucose units by maltase enzymes. During fermentation, yeast converts the sugary wort into actual beer by producing alcohol, a wide range of flavours and carbon dioxide (which is used later in the brewing process to carbonate the beer. Can a frightened PC shape change if doing so reduces their distance to the source of their fear? As the beers enter the stationary phase, yeast growth slows down. To begin the fermentation process, the cooled wort is transferred into a fermentation vessel to which the yeast has already been added. Such mixed fermentation involving different yeast strains adds a complexity to the beer flavor. You will get some action with in the first 24 hours of pitching your yeast but not a lot. Facebook Group During wort making fermentable sugars from malt are combined with the flavor and antioxidant Different strains of beer yeast will do different things when fermented in beer. The first evidence that shows fermentation is underway is the presence of bubbles in the airlock. ), Exponential Growth Phase: One to Four Days. Learn how and where you too can join the hunt for novel yeast strains. Most common yeasts are distillers and bakers. Making statements based on opinion; back them up with references or personal experience. This website uses cookies to improve your experience while you navigate through the website. For example, a malt that is roasted lightly gives a pale beer while heavily-roasted malt produces dark-colored beer. The kraeusen falls, and yeast begin to settle out, or flocculate. I know my lager will ferment but the wait, gets me every time. Pipewrench Gigantic Brewing. Once bottled, ales (bitter, IPA, stout, etc.) No-rinse sanitisers such as Star san take just a few minutes to sanitise everything. }); Professional breweries cool the contents of the fermenter gradually to 35 to 40 F, which forces most of the yeast to flocculate. If the beer being made is an ale, the wort will be maintained at a constant temperature of Primary During the first stage, the yeast performs aerobic respiration, and undergoes a series of changes to adapt to its new environment, hence the name Adaptive Phase . Post-apoc YA novel with a focus on pre-war totems. You never master brewing; Ive been making beer for over 25 years now; Im still learning all the time. The time of soaking is about 40 hours. You also have the option to opt-out of these cookies. The frothing results from the evolution of carbon dioxide gas, though this was not recognized until the 17th WebA Guide to Beer Fermentation Fermentation is a process whereby yeast converts glucose in the wort to ethyl alcohol and carbon dioxide gas (CO 2) to give beer its alcohol content and carbonation. There are several ways of doing this and, depending on what equipment you have, it usually takes around six hours. If youre new to home brewing, the chances are youve got a lot of questions that need to be answered before getting started. Additional processing depends on the type of beer that has been produced. A common method that a brewer uses to evaluate the extent of endosperm wall breakdown is to measure the endosperms acrospire. Then, the yeast starts to divide. The brewer prevents complete germination through drying, which forms the next phase of malting. What is yeast doing during beer fermentation? Some types of craft beer, including lagers, Lambic, and Trappist beers may take considerably longer. Terms and ConditionsPrivacy PolicySite Map, linked to lowering risks of diabetes, strokes, and cancer. There are one to five genes in yeast DNA that turn on in response to maltose, allowing for fermentation by brewers yeast. On average, fermentation takes at least two weeks to complete. During the first stage, the yeast performs aerobic respiration, and undergoes a series of changes to adapt to its new environment, hence the name Adaptive Phase. Much the same way that humans need 100 percent of essential vitamins and minerals to make it though the day, yeast cells also need 100 percent of their vitamins and minerals (nutrients) to make it through a fermentation properly nourished. Steeping helps the brewer extract color and flavor from the malt, which contributes to the final beer flavor. WebThe active phase usually lasts from 4 to 8 days depending on: Beer style Yeast used Pitch rate Temperature of the fermentation Could my planet be habitable (Or partially habitable) by humans? Though fermentation usually uses only a specific type of yeast cells, brewers may use a mixed fermentation process for specific kinds of beer. WebThe fermentation time of beer will depend on the yeast and the sugars present in the wort, the liquid that eventually becomes beer. Primary During the first stage, the yeast performs aerobic respiration, and undergoes a series of changes to adapt to its new environment, hence the name Adaptive Phase . In a lager fermentation, there are three stages, and knowing these stages can help you understand why we do certain things when making a lager beer. The impact of yeast on beer is unique and deserves a special mention. There will be no bubbles in the airlock during this period, and it The beer becomes clearer and develops its final flavour. If this happens, youll need to rouse the yeast back into solution. This is during the first 72 hours of fermentation. WebA Guide to Beer Fermentation Fermentation is a process whereby yeast converts glucose in the wort to ethyl alcohol and carbon dioxide gas (CO 2) to give beer its alcohol content and carbonation. The process is divided into four stages: brew day, fermentation, bottling, and bottle conditioning. Understanding the processes taking place during fermentation makes for better brewing. When yeast are pitched into beer they begin a process of acclimation to the environment known as the lag phase. Fermentation is usually divided into three stages: primary, secondary, and conditioning (or lagering). They evolved over time in Germany, where people started brewing in cooler caves. Once the wort has cooled to the correct temperature, generally between 18 and 22 C (65 to 71 degrees Fahrenheit), it can be transferred to the fermentation vessel.if(typeof ez_ad_units!='undefined'){ez_ad_units.push([[250,250],'homebrewjournals_com-large-mobile-banner-1','ezslot_6',198,'0','0'])};__ez_fad_position('div-gpt-ad-homebrewjournals_com-large-mobile-banner-1-0');if(typeof ez_ad_units!='undefined'){ez_ad_units.push([[250,250],'homebrewjournals_com-large-mobile-banner-1','ezslot_7',198,'0','1'])};__ez_fad_position('div-gpt-ad-homebrewjournals_com-large-mobile-banner-1-0_1');.large-mobile-banner-1-multi-198{border:none!important;display:block!important;float:none!important;line-height:0;margin-bottom:15px!important;margin-left:auto!important;margin-right:auto!important;margin-top:15px!important;max-width:100%!important;min-height:250px;min-width:250px;padding:0;text-align:center!important}. Chill to 10C (50F) first and keep at this temperature for 48 hours, 2. So, what exactly is yeast?